(Held at Aachen, Germany, on Nov. 12-14, 2003)

Dec. 11, 2003

[Posted on Dec. 11, 2003]

Editor's

Note (Toru Nakagawa, Dec. 11, 2003)

This is a personal report of ETRIA Conference held a month ago. (See ETRIA Official Web site.) About 70 people attended at the conference and presented/discussed a wide range of TRIZ research and applications. Summarising and reviewing important papers and activities in these conferences should be of interest and worthy to learn for many readers, I suppose. Thus, I have written a personal report of the conference and am posting it here in my Web site, as I did so far for all the TRIZ confereneces I attended (See ETRIACon2002 and TRIZCON2003). Even though I am trying my best to understand and review the papers in fair ways, please regard this as a personal view and please correct me if there is any mistake/misunderstanding in this report.

Conference Name: ETRIA World Conference:TRIZ Future 2003

Main Theme: Worldwide Best Practices in Systematic Innovation through Automotive Industry

Date: November 12-14, 2003

Place: Technologiezentrum am Europaplatz, Aachen, Germany

Held by: European TRIZ Association (ETRIA)

Organized by: [WZLforum; Laboratory for Machine Tools and Production Engineering (WZL); and Fraunhofer Institute of Production Technology (Fraunhofer IPT)],

RWTH University (Rheinisch-Westfanische Technische Hochschule),

Aachen, Germany

Participants: about 70 people from 17 countriesOutline of the Agenda: 1 Keynote Speech and 32 presentations in single track from 9:00 through 18:00 for the three days.

Overview:

This is the third World Conference on TRIZ organized by ETRIA (European TRIZ Association). The first one was held at the University of Bath, UK (See my personal report of ETRIA2001), and the second at ENSAIS University at Strasbourg, France (personal report of ETRIA2002). This year, the Conference was held at RWTH University, Aachen in Germany.

Fraunhofer IPT and Laboratory for Machine Tools and Production Engineering (WZL) of RWTH University Aachen are the core of the organization. Professor Dr. Guenther Schuh served the Chairman of the Conference and Mr. Markus Grawatsch worked as the key person for realizing this conference. Dr.Denis Cavalluci gave a brief introduction talk as the new President of ETRIA.

The total number of participants was about 70 according to the list of participants distributed during the conference (plus several as the staff). Participants came from the following 17 countries (according to my counting with the list): Germany (29), France (10), The Netherlands (6), Belgium (3), Italy (3), Japan (3), Brazil (3), UK(2), USA (2), Austria (2), Czech Republic (2), Belarus (2), Slovenia (1), Israel (1), India (1), Korea (1), Mexico (1), unknown (1). Noticeable is the participation of many industrial people from Germany, and of TRIZ colleagues from India, Brazil, and Mexico.

Keynote Speech was given by Vladimir Petrov, Master of TRIZ from Israel, for an hour on the second day. All other papers were presented in 30 minutes in single track, with intervals of lunch and morning/afternoon coffee breaks. In most cases only short time was available for official Q&A in the session.

The Proceedings were provided in two thick bound folders of A4 size. Each presentation is normally composed of a profile page, paper itself, and slides; while some misses either paper or slides. A list of the papers in the Proceedings are shown at the end of this page in its original order. The papers are presented in this order with minor exceptions: a few papers were not presented (shown with the "--" marks); Nakagawa's presentation was orally given in the slot of Poster Session as shown at the end of the list. Papers are referred with the numbers in this list as shown in [ ].

Topics

of the

presentations

cover a wide range, while the sessions seemed not arranged in any clear

categorization. As shown in the main theme, the present

conference

featured in a large number of reports from automotive industries in

Europe,

talking about experiences in promoting and applying TRIZ. In this

report I am going to group them in the following categories:

(A) Keynote Speech

(B) TRIZ

Case Studies in

Automotive and Other Industries

(C) TRIZ

Promotion

Experiences in Automotive and Other Industries

(D) Enhancing the TRIZ Methodology

(E) Integration

of

TRIZ and Other Related Methods

(F) Patent Analysis in TRIZ

(G) Application of

TRIZ in Non-Technical

Area

Some Concluding Remarks are described after these reviews.

(A) Keynote Speech

The Keynote Speech [II-1] was given by Vladimir Petrov, Master of TRIZ, with the title of "TRIZ - past, present and future". He says "the essence of TRIZ is the discovery and use of laws, regularities and tendencies for the development of technological systems" and showed bibliography in Russian, English, and German. History of TRIZ development was shown in 12 slides, itemized in the chronological way. It is quite interesting to learn that various theories and tools in TRIZ were formed gradually, sometimes in sequence and other times in parallel, for many years. I personally asked Mr. Petrov to make a one-page chart of the history, but he said "It's impossible. I have written 600 pages of TRIZ History!" In the latter part of his lecture he listed up current shortcomings of TRIZ and their future in various aspects, including aspects of theory, education methods, education of teachers, development of TRIZ community, and development of scientific schools.

Petrov

[I-13] also gave a talk on "New system

of Standard Solutions of Inventive Problems". Historically,

"Standards"

(of 29 laws) were developed during 1975-1979, and "Systems of

Standards"

(of 76 laws) during 1981-1985. He has extended the idea and has

formed

"New Systems of Standards" of 150 laws. So he showed names (after

names) of those (new) laws in a hierachical numbering system. He

has used this new system for these three years in education and problem

solving successfully, he says, and still wants to make it more complete

and universal before publication.

(B) TRIZ Case Studies in Automotive and Other Industries

Now I am going to review practical papers reporting on case studies and promotion experiences in industries, prior to theoretical papers, because the Conference put much stress on them as the main theme and obtained a lot of fruits.

In the automotive industry, Pascal Guerry (MGI COUTIER, France) [I-7] reported his trials of applying TRIZ to his real problem. The problem is how to separate droplets of rain from the air in the car air-intake line, especially prior to the cartridge air cleaner. Their first concept was to use quibbles. According to the test, this worked in the air blowing but did not in the air aspiration situations [Fig. 1a]. So they applied TRIZ, especially first four steps of ARIZ, i.e. Operating zone/time, Resources, Physical contradiction, and Ideal final result. They obtained 15 ideas, including puting a box [Fig. 1b] or an acoustic resonator around the pipe. Their intermediate solution succeeded in the droplet separation but caused pressure decrease. Thus they applied TRIZ again to solve the contradiction, and found a solution which introduced a hole for the Bernoulli effect at the optimal position suggested by the flow analyis [Fig. 1c]. Their third prototype revealed the water separation of 80% without quibble nor extra pressure drop.

[Fig. 1a,b,c: Not shown here because a permission is not given yet.]

Guerry summarizes the signifficance of his paper in the following scheme [Fig. 2; Redrawn with Nakagawa's understnding]. This corresponds to the idea of "Chain of Contradictions" in Darrell Mann's textbook "Hands on Systematic Innovation" (CREAX, 2002) and represents sound and powerful attitude in technology develoment.

Dominique Benoit and Chris Rhodes (ArvinMeritor, France) [II-6] also reported a TRIZ case study for reducing the noise from the vehicle door. The company has introduced TRIZ since 2001 in two projects assisted by INSA Strasbourg. With some experiment they have found that the noise problem most significantly occurs at the top-behind section of the door which gets loose because of the sucking-out force caused by the aerodynamic effects during high-speed driving. The simplest idea is to make the door seal thicker, denser, and multiplied, but it would request the passengers to make harder efforts for closing the door. Then by applying TRIZ Separation Principle in time, the project has found that the seal can be soft while closing the door (when the car is stationary) and can be tight while driving at high speed. This solution has been realized with a new idea of inflatable seal with an "inflatable joints" using the pressure difference generated by the aerodynamic effects of the speed. (The solution is shown in a few slides but unfortunately not clear enough to me due to the lack of a full paper.)

Edgardo Cordova Lopez (Benemerita Universidad Autonoma de Puebla, Mexico) [II-8] reported his activities at Volkswagen of Mexico. Problems to reduce the rework ratio in the casting with a sand mold were tackled. The main process applied is to interpret Inventive Principles suggested from the Contradiction Matrix. Even though the analysis process seems elementary, the author obtained a solution of the return-scrap hopper with more perforation and vibration for fully separating the sand. The implementation has resulted more than 10% of reduction of scraps in the casting. This led the managers to organize a TRIZ course in Volkswagen of Mexico and many people to want to learn TRIZ in Mexico, he says.

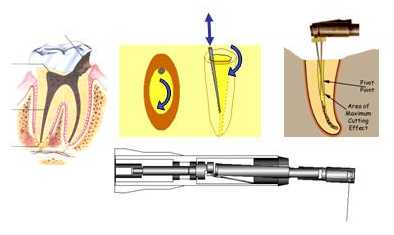

An excellent case study was reported by Ellen Domb (Editor of the "TRIZ Journal") and her customer/friend John "Jack" Jacklich (USA) in the field of dentists' tools. Dr. Jacklich is a dentist and the developer of "washed field technique" and related tools in dental operation (inside teeth) since 1972. In 1997, he took Ellen Domb's class "Practical Innovation: A TRIZ Learning Event" (See TRIZ Journal, April 1997). Though the class was a conventional presentation of TRIZ for biginners, the students were advised to identify their own past use of the tools/methods of TRIZ. Dr. Jacklich quickly mastered the essence of TRIZ and has been using the concepts of IFR, Technical/Physical Contradictions, 40 Principles, and Scientific Effects since then, resulting much improved designs and quicker cycles in his innovation.

The paper shows three actual cases of Dr. Jacklich's inventions and further improvements with the help of TRIZ : (a) Periodontal intraligamentary syringe, (b) Fine-cut endo cartridge syringe, and (c) Circumferential filing. Since there is not enough space here to explain the problem and the solutions, I have just chosen to show figures with which you will be able to imagine the tool operation. [The authors have given a permission for me to post the paper in Japanese translation in near future.]

Ian Mitchell (Ilford Imaging, UK) and Darrell Mann (CREAX, Belgium) reported a practical approach of breakthrough innovation in constraint-dominated situations. Being faced with the prevailing shift towards digital cameras, the batch sizes for photographic paper manufacturing have to be reduced. A problem occurred in the mixing process, where an amount of water is chilled and then some powder is mixed to disolve. The mixing vessel shown in Fig 4a has hit its limit in batch size reduction at 106kg, causing much longer time for chilling and for mixing due to inefficiency in the situation out of its original design.

The team examined the problem with Functional analysis and by asking "what was stopping the various problem areas from being improved?". They found a number of technical and physical contradictions, and obtained suggestions of Inventive Principles with the help of CREAX's new Contradiction Matrix. The uniqueness in the present paper is that some of the Inventive Principles were filtered out with the constraints imposed. They imposed the constraints on themselves that the product must not be affected, the existing hardware must not be replaced, energy consumption must be small, and the cost of new installation must be minimal. The Fig. 4b shows their intermediate solution, with still insufficient efficiency.

At that time the bearing of the Impellor shaft was broken. This urged the team to trim the Impellor and to fully utilize the Pump, the least-used Resource in the original design. As shown in Fig. 4c, the water is chilled by splaying onto the part of vessel wall where the Cooling jacket is installed and then is stirred for dissolving the powder with the circulated water flow. This solution achieved the batch size reduction to less than 50 kg and also efficient chilling and mixing, with minimal investment. [Note: These figures were shown in the slides but not recorded in the Proceedings. Nakagawa has modified Figs. 4b and 4c so as to better match with the description in the paper. The paper will be posted in Japanese translation in this Web site in the near future.]

The paper [II-16] by Pavel Jirman (Technical Univ. of Liberec, Czech Rep.), Bohuslav Busov (Technical Univ. of Brno, Czech Rep.), and Alexander Skuratovich (Belarus) presented their observation on the development trends of glass moulds. In the paper, after the description of the mechanism of the glass-bottle manufacturing process with glass moulds, the authors examine several laws of technological evolution by turn to reveal actual mechanisms which may be interpretable as the reflection of the laws. Many photoes were shown in the presentation but not recorded in the Proceedings; thus it is difficult for me to follow the detailed observations.

The paper [I-9] by Serguei Khrouchtchev (Moscow State Technical Univ. named after Bauman, Russia), even though not presented orally, is an excellent analysis of the development of laser optical disk systems. The author made a powerful cost-reduction invention of the DVD pick-up optical system at Samsung Electronics, Korea, during 2000-2002, as reported by Hyo June Kim at the 4th Japan IM User Group Meeting held on Sept. 12-14, 2003. The paper [I-9] reviews the up-to-date development of technology in laser optical disk systems and discusses about the problems/contradictions and their solutions in terms of TRIZ principles.

Michael

Schlueter (Philips Semiconductors GmbH, Germany) [I-17]

discusses a case of improving software algorithm. An

algorithm

of the n2 order was improved into the one of the 2n

order

by inserting a sorting process. The author writes: "At first

glance

TRIZ doesn't seem to apply to software problems: no atoms, no

molecules,

no layers to touch; no physical, no chemical effects to apply.

However,

software provides functions, it is made from parts and resources, and

software

can be ideal or less ideal." This statement is quite right, but I

still feel that software people could find the above algorithm

relatively

easily in their own expertise without somewhat indirect suggestions in

TRIZ terms. Introducing TRIZ into software development area still

needs further study, I feel.

(C) TRIZ Promotion Experiences in Automotive and Other Industries

Six papers were presented in this category from automotive industries in Europe (Germany and France). This is one of the most remarkable achievements in the present Conference.

Guillaume Dupont (ENSAM Paris, France) and Marcel Monnier (PSA Peugeot Citroen, France) [I-12] reported their experiences of deploying TRIZ in PSA Peugeot Citroen (2nd European car manufacture, having about 200,000 employees). The company first learned TRIZ in 1998 through a TRIZ software (IWB), and started a project for trial deployment of TRIZ in 2001. They set three levels of expertise as their goal: (1) Basic level (with a short lecture), (2) Simplified use of TRIZ (after 2-day TRIZ training), and (3) TRIZ specialist level. The level 2 training has started since the first quarter of 2003. Since there are no level-3 specialists at moment in the company, external TRIZ specialists are called for conducting case studies. Feedback from 27 trainees is reported about their usage of TRIZ tools with ranks from 5 (always) to 0 (never): Questionaire = 4, Problem Formulation =5, Contradiction Matrix =5, Separation Principles =3, S-Fields =2, Laws of Evolution =2, ARIZ =1.

Eckhard Schueler-Hainsch and Christine Ahrend (DaimlerChrysler AG, Germany) [II-14] reported their experience of applying TRIZ concepts of Trends of Technical Evolution. The major task of the authors' division (i.e. Society and Technology Research Group) is looking for future trends in society and their implications on technology and products (related to their company). Thus the authors organized a task force for foreseeing the future trends of customer requirements. They focused on a rather standard group of customers, i.e. age of 30-45 years, family households, middle class car, and medium to upper segment of income. As a result of intensive customer interviews (up to 2 hours each), three subgroups of customers were assigned (by using Grounded Theory Methodology) being characterized with their requests for (a) Function and innovation, (b) Relief and confort, and (c) Family and fun.

The the

foreseeing

task

was submitted to a TRIZ-based taskforce of 12-14 researchers

including

senior managers. The taskforce conducted 4-step workshops, where

the 1st and 4th workshops with all the members together, while the 2nd

and 3rd workshops with split members in parallel for speeding up the

group

communication. The project office worked during the intervals of

the workshops. The main objectives of the workshops were:

| 1st WS: | Kick-off:

Definition of the most

important

vehicle functions, and Collecting technologies already existing and in research pipe line. |

| 2nd WS: | Generating

ideas: Completing

problem statements,

and Generating ideas on the basis of the laws of technological evolution |

| 3rd WS: | Integration of

concepts:

Assessment of generated

ideas, Identification of concept kernels, and Integration of ideas to vehicle concepts |

| 4th WS: | Concept discussion: Discussion and agreement on three different vehicle concepts. |

In one of the 2nd workshops, being requested by the participants, they tried to teach TRIZ to the participants, but explanation of TRIZ was rather hindering the process. So later TRIZ was not taught but used to stimulate participants thinking; this was much a success, the authors say. The taskforce obtained clear concepts of three different vehicle types, though such concepts themselves were not reported in the Conference, of course.

Nicolas Gombert (Hutchinson, France) [II-17] reported the experience of introducing TRIZ in Hutchinson, world market leader in the industrial rubber sector having markets in automotive and aerospace industries and consumer products. The company learned TRIZ in 1998 and started an experimentation in 1999 with 2 students of INSA Strasbourg. The results of the experiments were so good that many departments wanted to have TRIZ experts. However, Huchinson found that TRIZ user (or expert) has to be trained well and has to perform regular practice; thus it decided to centralize the expertise into one specialist shared by all the departments. Thus the keyperson in TRIZ, i.e. the author, has been trying to promote TRIZ in internal Web site, in communications with many department, and to train himself in the courses of INSA Strasbourg and Invention Machine software. He summarized the achievements as: Since 2000 TRIZ represents about 3-4 studies per year; 5% of the result idea are filed as patents; Each sector of Hutchinson world wide has ever used TRIZ at least once. The idea of sharing the centralized TRIZ expertise should be practical and fruitful in many organizations.

Denis Cavallucci, David Oget, Michel Sontag, and Nathalie Gartiser (INSA Strasbourg, France) [II-5] reported with the title of "About non technical barriers preventing efficient TRIZ integration into organisations". This report reflects INSA's experiences of promoting TRIZ for these 7 years in about 50 companies, they say. The topics of their TRIZ application are summarized in Fig. 5. Automotive industry is appearently most active in introducing TRIZ.

The first postulate by the authors is: "TRIZ is formally acknowledged as an efficient way of addressing technological problems. However, the difficulties of its acceptance by organizations confronted with the problem of its integration are very significant." The attitudes of organizations to TRIZ (or any other new methodology/concept) may be characterized as shown in Fig. 6. The authors have found a number of basic differences between conventional corporate culture and the TRIZ philosophy, in the fields of educational, management, and cognition sciences.

The authors thus propose non-technical consideration to be taken prior to the development of a TRIZ action. The scheme is quite generic (i.e. applicable to the introduction of any other new methodology), as shown in Fig. 7.

-- One point we

should

notice here is the way of our presenting TRIZ itself. The typical

or classical way of presenting/teaching TRIZ is too much ellaborated

and

time-consuming, I think. We should teach TRIZ in its essence in a

much easier and useful way. USIT approach (Nakagawa, [II-24])

is such a trial.

(D) Enhancing the TRIZ methodology

Dennis Murnikow (TriSolver Group Germany, Germany) [II-7] reported how the innovation and problem solving projects can be supported in TRIZ, or more strictly with their software tool "TriSolver". He discusses about innovation projects in the following 5 steps:

(a) Formulating the innovation tasksWhile new product development needs all these steps, improvement of an entire technical system needs (b) through (e), and small system modification needs (c) alone, he says. In the process (a), an effective method of using Trends of Technology Evolution is explained as "Technical driven innovation", with emphasizing the necessity of "Customer benefits driven innovation". The whole article is a nice introduction to their well-structured and easy-to-use software tool, "TriSolver".

(b) Analyzing initial situation (current technical system)

(c) Solving problem (idea generation)

(d) Evaluating ideas

(e) Developing and evaluating concepts

Elena Novitskaya (Educational center "Universum", Belarus) [I-11] demonstrated the importance of transforming good ideas to different technical systems. The key concepts are Trends of evolution and structural similarity. Being a professional designer and TRIZ specialist, she has demonstrated a lot of beautiful drawings of examples of transformation results, which are instructive for engineers as well as for children.

Peter Chuksin (LG Electronics, South Korea) [II-20] talked about their method of forecasting technical systems, especially in their structural and functional anaysis. However, since his work on current technical systems in the company was not allowed to publicize, he took an example of historical development of the grain-harvesting combine devices.

Sebastien Dubois, Phillippe Lutz, and Francois Rousselot (INSA Strasbourg, France) [I-8] is a proposal to make TRIZ (or ARIZ) easier to use with the aid of Atriticial Intelligence. ARIZ and Inventive Standards are formally modeled in the object-oriented style (i.e. a style of software programming), as a collection of rules to be applied on knowledges of problem situations. To make the knowledge acquisition of a concrete problem manageable to users, they installed a set of "Heuristics" of questionaire. While replying the questions one after another as guided by the computer, the problem situation is formed in the computer, especially in the style of physical contradiction. Then, hopefully, solutions or solution triggers are suggested by the computer as a result of application of TRIZ rules. -- Even though a case of solution is illustrated in the paper, it is not clear to me how it comes out. Interesting work, but still a long way to go, I suppose.

Alla Nesterenko (TRIZ Specialist, Russia) [II-22] reported a paper (though not presented orally) in a similar to above [I-8] but slightly different direction. She uses the ENV model (i.e. Element, Name of feature, and Value of feature) in the OTSM-TRIZ approach (i.e. the approach led by Nikolai Khomenko) as the basis. Then she reported the framework to formulate the followings: properties, effects, laws, and TRIZ solution rules. This formulation is somewhat silimar to the style reported in Dubois et al. [I-8], but meant to assist human specialists/learners to think in a more formal way to find new solutions to their own problem.

Prakash R. Apte (Indian Institute of Technology at Bombay, India) [I-14] presented a paper composed of two parts. In its first part, he puts stress on the use of Effects knowledge base to see/utilize various methds for any target function. As an example, he chooses the function of "moving an object through small/precise displacements". The following methods can be used in the increasing order of fineness: Pantagraph, micrometer screw, worm wheel, stepper motor, stepper motor with micrometer screw, and then stepper motor with worm wheel. Here comes the limit of mechanical system because of back-lash. Then, we know about Piezoelectric actuator useful in the sub-micrometer region. Then, what next? Magnetostrictive actuator for nanometer displacement, he says. "Change in the Field" is the key to think about this kind of jumping over limitations, he says.

Pavel Livotov (TriSolver Group Europe, Germany) [I-16] discussed the role of TRIZ in sustainable and disruptive innovation process. These two types of innovation process are defined as:

|

|

|

|

|

The author proposes a method for evaluting the maturity (called as "System Value: Vs") of a technical system quantitatively with the importance-weighted average of satisfaction level for a large number of needs. In this measure, he suggests that sustainable innovation with notable success can be obtained with a certain degree of increase DVs ranging from 25% (when Vs is up to 50%) to a few % (when Vs is around 80%) and that the disruptive (breakthrough) innovation may need additional increase by about 10%. It is also noted that in a highly matured system (with Vs > 85%) disruptive innovation can be obtained only by introducing/meeting new user needs.

Thus the author concludes: "The future TRIZ development should be focused on: identification of true user needs, evolution of existing needs, and prediction of new needs. This, in turn, allows to define what functions and systems will be required to meet these new needs. This knowledge also makes it possible to discover radically new directions of technical system evolution." (Note that this statement is based on the recognition that "System is to provide Functions, and Functions are to satisfy Needs".)

Toru

Nakagawa (Osaka Gakuin Univ., Japan) [II-24]

gave an oral presentation (at the Poster Session) with the title of "USIT

approach in Japan for simpler and powerful process of creative

problem

solving in TRIZ". Simplification of TRIZ should be the key for

TRIZ

to be widely adopted in industries. Essence of TRIZ can be

expressed

in 50 words, and the process of problem definition (including root

cause

definition) and problem analysis in terms of Objects, Attributes,

Functions,

Space and Time can be achieved in a straightforward way in USIT.

Also all the tools of TRIZ (including Inventive Principles, Inventive

Standards,

Trends of Evolution, and Separation Principles) have been reorganized

and

unified in the USIT solution generation methods. In Japan the

author

has conducted 2-day USIT training seminars in industries, where

TRIZ/USIT

is introduced to beginners and 3 real industrial problems are solved

successfully

in parallel along the full course of the USIT process. USIT

method

has been adopted in several manufacturing companies in Japan. --

This is a refrain of the main theme Nakagawa has been writing about in

his Web site.

(E) Integration of TRIZ and Other Related Methods

One of the important themes in the Conferrence is to view TRIZ in a wider scope of technology and product/process/service development and to try integrating it with other methodologies. Several papers were reported in this direction from both practical and theoretical aspects.

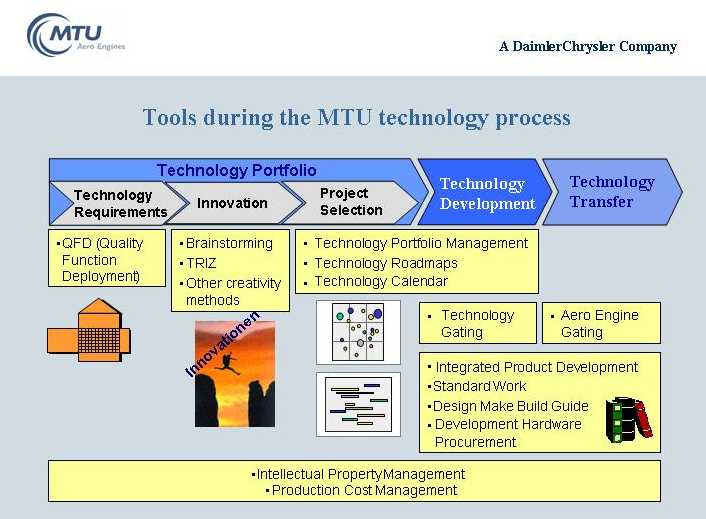

Thomas Novacek (MTU Aero Engines, Germany) [II-4] reported the introduction of TRIZ into the company's R&D process in one of DaimlerChrysler Companies. Fig. 8 shows the overall view of the technology process in MTU. TRIZ is assigned as an important methodology in the Innovation step of the Technology Portfolio phase. A number of TRIZ workshops (i.e. projects) have been conducted since 1999 and TRIZ and other innovation methods have also been introduced/accumulated.

Andreas Jost (DaimlerChrysler Research and Technology, Germany) [I-6] reported that the well established System Dynamic problem analysis and modeling method (developed in MIT) provides a foundation of using TRIZ. Especially the System Dynamic Cause and Effect Diagram can smoothly be used as the input data of TRIZ Problem Formulation. Capability of simulation in System Dynamic is also valuable in complementary use of the two methods, the author suggests.

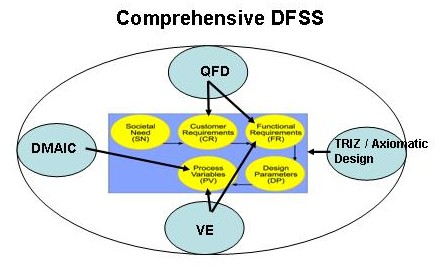

Michael S. Slocum (Breakthrough Management Group, USA) [II-9] advocates "the integration of QFD, TRIZ, and Six Sigma in an axiomatically driven Total Product/Process Development System (TPPDS)". The follwing figure shows his scheme of the comprehensive DFSS (Design for Six Sigma):

In the above scheme TRIZ can be used in the following points: (a) In identifying Social Needs, to focus on identifying and resolving contradictions; (b) in identifying Customer Requirements, to derive concepts with TRIZ structured approach based on empirical observations, heuristics from patents and technological evolution, functional modeling, and contradiction identification; (c) in identifying Functional Requirements, to analyze with Su-Field modeling and MLP (SLP?); (d) and to assist in identifying Design Parameters and Process Valiables. This paper does not show any example.

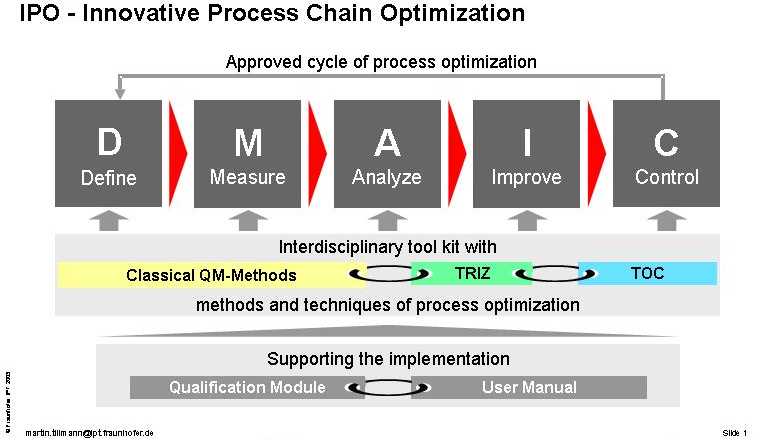

Tilo Pfeifer and Martine Tillmann (Fraunhofer Institute for Production Technology, Germany) [II-10] reported their approach for Innovative Process Chain Optimization (IPO) by integrating TRIZ, TOC (Theory of Constraint), Classical Quality-Management Methods, and Six Sigma. The research project was accomplished by a work group of representatives coming from different industries and was validated in two pilot applications, the author says. Their scheme, whose framework of DMAIC being taken from Six Sigma, is shown in Fig. 10.

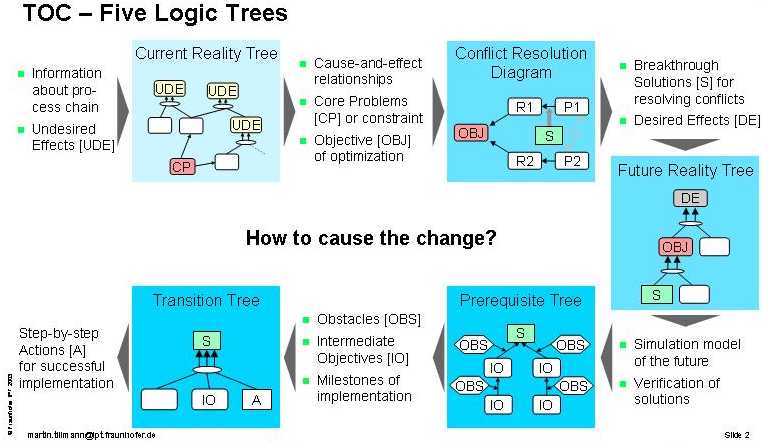

The Theory of Constraints is: "Production systems consist of process chains, whose quality depends on the weakest link." TOC's thinking process is to answer three basic questions: "What to change?", "What to change to?", and "How to cause the change?". The thinking process is supported by the tools of "five logical trees" as shown in Fig. 11.

In the Analyze Phase, TOC is used to derive the Current Reality Tree and Conflict Resolution Diagram. Then, in the Improve Phase, TRIZ can contribute much to create breakthrough solutions. By use of Portfolio Diagrams of chance vs risk and cost vs time, right solutions are chosen, and they are further checked with the succeeding TOC tools to safeguard their successful implementation. -- This paper has clearly shown the logic for innovative improvement in production process by complementary use of TRIZ and TOC.

Zahir Messaoudene (INSA Strasbourg, France) [II-12] discussed about a theoretical method for formulating problems in a system of manufacturing process. In order to implement the idea of Lean Manufacturing (by J.P. Womack, 1996), the author has proposed a method of representing networks of relations among functional needs, design parameters, activities, and performance indicators. For reducing the manufacturing time, for instance, it is desirable to reduce lot delays (resulting from the batch of transfer) and run-size delays (resulting from the manufacturing batch) simultaneously. These functional requirements are interpreted in terms of associated design parameters and performance indicators, and thus a large number of contradictory reqirements are revealed in the matrix-style representation. This opens the possibility of applying TRIZ to solve such contradictions in designing lean manufacturing systems, the austhor says.

Jan C. Aurich and Karsten Jenke (University of Kaiserslautern, Germany) [II-13] also put stress on the problem solving in manufacturing processes. They discuss about their development of a holistic concept of a systematic management for solving technical problems in manufacturing processes. They are going to embed TRIZ tools as the major elements with interfaces to several complementary tools. The project seems to be at an initial stage.

Markus

Grawatsch (Fraunhofer Institute for Production

Technology,

Germany) [II-19] discusses about TRIZ-based

method of Technology Intelligence (i.e. to identify and forecast

global

technology road map). Such Technology Intelligence is necessary

for

corporations prior to setting up their Technology Planning (i.e. to

decide

corporate-specific technology road map). TRIZ can contribute much

to Technology Intelligence, providing tools of Trends of technological

evolution and related ones. The author suggests the following

usage

of TRIZ: (a) to define framework of examination (with Function Analysis

and 9-Windows method); (b) to identify alternative technologies (with

Effects

database and construction catalog); (c) to define long-term development

targets (with the concept of Ideality), and (d) to anticipate

development

directions (with Evolutionary patterns).

(F) Patent Analysis in TRIZ

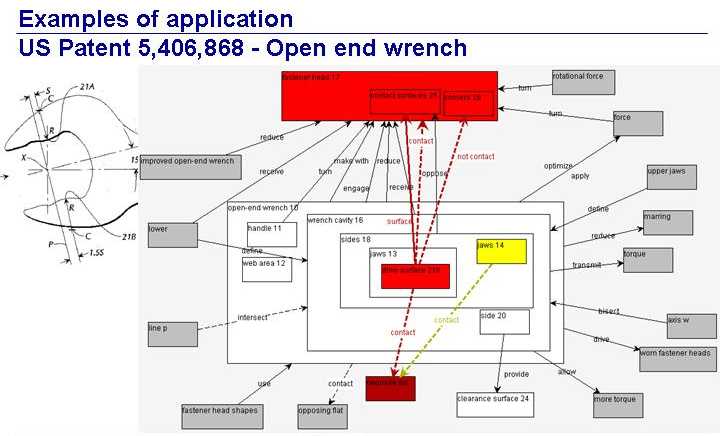

Gaestano Cascini and Paolo Rissone (University of Florence, Italy) [I-10] reported a sophisticated software tool "PAT-Analyzer" for speeding up patent analyses. The key methodology adopted in the tool is the functional analysis supported by (external) semantic analysis of the patent texts. By scanning the patent text, the tool automatically identifies all the components, identifies subsystem/supersystem relationships (hence defining a hierarchy of detail/abstraction levels), and determines positional and functional interactions between the identified components (by filtering the list of Subject-Action-Object triads to eliminate unrelivant triads).

On the basis of the information thus obtained, a few types of graphs can be drawn as the summary of each patent. An example of application is shown for the case of US Patent 5,406,868 "Open end wrench". This patent is unique in profiling the working faces of the wrench such that the points of contact with the nut avoid the damage-prone corners. By processing the patent text, the tool generates the figure as shown below. Hierachical structure of components are shown with the enclosure relationships of rectangles, while the functional relationships are shown with arrows (with the standard convention in TRIZ for distinguishing useful and harmful functions). Most specific (i.e. most detailed) components and functional relationships are highlighted with colors, in order to guide users' focus for understanding the peculiarity of the patent. This highlighted parts can be read as: "drive surface 21" of the "jaws 13" of the "wrench cavity 16" -- "contact" -- "flat surfaces 25" of the "fastener head 17", but "not contact" -- its "corners 26". This is certainly a meaningful summary of the patent, extracted automatically by the tool.

Barry Winkless (CREAX, Ireland) [II-15] reported their patent analysis research (presented by Darrell Mann in stead). They use the information of both backward citation counts (i.e. the patent cites older patents) and forward citation counts (i.e. the patent is cited by later patents), and try to interpret the information in comparison with the ideas of levels of inventions, originality, and generality. Even though the CREAX' patent research has already achieved a lot as reported at TRIZCON2003, the current presentation is at its stage of "a first look" as its title says.

Siegfried

Luger (Luger Research, Austria)

[II-18] also proposed a method for evaluating patents, by

using

"Patent Index". His index is based on the model of Function

(performance)

S-curve, which is hierarchically composed of Component S-curves and

Parameter

S-curves. The parameters are benchmarked (with the Trends of

technology

evolution) in height (innovation level), in depth (innovation steps),

and

in breadth (number of trends), and then the patent indices of

components

and the patent are calculated with them. The author tried to

validate

the method in the case of lighting electornics.

(G) Application of TRIZ in Non-technical Area

Two papers were reported in this category:

Atsuko Ishida (Hitachi, Japan) [II-21] reported a new approach to "Apply TRIZ to Create Innovative Business Models and Products". While there have been a number of trials to re-interpret TRIZ technical principles in business terms so far, the author made one step further to build "Business idea database" first and then to provide a number of suggestions for triggering concrete business ideas.

Her idea is based on a concise definition of three "comon business/product strategy": (a) Expand business/products' functions, (b) Concentrate business/products' functions, and (c) Change business/products' structure. For each strategy, improving and degrading features are listed up, and such features are interpreted in terms of parameters for Contradiction Matrix (in technology). Corresponding to pairs of such improving and degrading features for a (business) strategy, Contradiction Matrix (in technology) shows a large number of Inventive Principles, which may be re-interpreted in business terms. (Segmentation Principle, for example, is interpreted as "Divide a system and summarize common functions"; while Taking-Out Principle as "Divide a system and eliminate useless functions.") In this manner, patterns of business ideas are accumulated in "Business Idea Database".

Users may use the Business Idea Database as a pool of concepts of business ideas; corresponding to user's situation, users may build up their business ideas by applying the concepts in their own choice. Then the conceived business model should be evaluated with a set of criteria, including scarcity, hardness to transfer, hardness to imitate, durability, hardness to substitute, customer power, and supplier power. The author has demonstrated two small examples. -- This paper talks at a high level of abstraction and seems to be widely applicable in conceiving business models and business strategies.

Nelly Kazyreva (Belarus-TRIZ, Belarus) [II-23] talked with a title of "TRIZ for people: psychological aspects". She discussed about NLP (Neuro-Linguistic Programming) and TRIZ, emphasizing the similarity between them especially at the points "What TRIZ-specialists can learn from NLP?" (Her paper is not easy to read for many people because of unfamiliar concepts of NLP and because of her writing in somewhat too Russian way, but having struggled with her paper, her slides are surprisingly clear to me.) NLP was founded in 1975 by Bandler and Grinder, and currently R. Dilt in St. Petersburg seems to be one of the most important thinkers in NLP.

NLP deals with human relationships. In the 9-Window method, while TRIZ puts a technical system at the central box, NLP put I (myself) there to model the world of problem. "Re-framing" is the important concept in NLP, implying to change our own thinking way from the frame of "problem" to that of "result", from "mistake" to "feedback", and from "impossible" to "if". Just like 40 Principles and other tools in TRIZ, NLP has a number of guiding ways of "re-framing" and "problem solving" in human-related areas. The author has been trying to make bridges between these two independently-established philosophies/methodologies, and has found that TRIZ has most (and some more) of the concepts essentially correspond to those of NLP.

Finally she concludes: "TRIZ' skills of personalities are a resource which is not fully used at present for solving personality and social problems. Mastering TRIZ and NLP together will make it possible (a) to expand own internal resources and "a map (i.e. the view) of the world"; (b) to create successful positive strategy of behavior in the varying world; (c) to model and use the behavior of other people; and (d) to solve internal and interpersonal conflicts.

Concluding Remarks

As described above, the ETRIA World Conference 2003 had brought in people working and being interested in TRIZ around the world. It was very valuable that people came from industries and academia besides specialised TRIZ consultants/promoters. Here are some of my personal impression:

Before closing

this Personal Report, we would like to express our sincere thanks

to the people and organizations who made this conference possible and

so

much success.

Proceedings are available at WZLforum. [The price is 300 Euro. (Dec. 17, 2003). Send an Email to WZLforum at k.marso@wzl.rwth-aachen.de ]

For next

year, ETRIA

World Conference "TRIZ Future 2004" is announced to be held

in Frolence, Italy, in autumn.

Details will be available in January, 2004. We are looking

forward

to meeting many of you at ETRIACON2004. (BTW: TRIZCON2004

being organized by the Altshuller Institute for TRIZ Studies is

going

to be held in Seatle, USA, on April 25-27, 2004. See you

there,

too!)

List

of Papers in the Proceedings

[--: Not presented orally.]

[Some papers posted in Web sites are shown with their URL and are

linked.]

[I-4]

Introduction:

Why's and How's of ETRIA

Denis

Cavallucci (INSA Strasbourg, France) (President of ETRIA)

[I-5]

Opening

Speech

Guenther

Schuh (WZL, RWTH Aachen, Germany)

[I-6]

Requirements

for systematic process innovation: System dynamics versus TRIZ?

Andreas

Jost (DaimlerChrysler Research and Technology, Germany)

[I-7]

TRIZ

approach

in an automotive supplier: MGI COUTIER

Pascal

Guerry (MGI COUTIER, France)

[I-8]

Proposal

of an Object-oriented model of the physical contradiction to facilitate

the problem-framing phase in design

* Dubois Sebastien, Lutz Phillippe,

Rousselot

Francois (INSA Strasbourg, France)

[I-9]

Analysis

and development aspects of laser optical disk systems

-- Serguei

Khrouchtchev (Moscow State Technical University named after

Bauman,

Russia)

[I-10]

PAT-Analyzer:

a tool to speed-up patent analyses with a TRIZ perspective

* Gaestano Cascini, Paolo Rissone

(University

of Florence, Italy)

[I-11]

Transformation

of structurally similar elements of technical system

Elena

Novitskaya (Educational center "Universum", Belarus)

[I-12]

Deployment

of TRIZ within PSA Peugeot Citroen and Experience Feedback

* Guillaume Dupont and Marcel Monnier

(PSA

Peugeot Citroen, France)

[I-13]

New

system

of standard solutions of inventive problems

Vladimir

Petrov (TRIZ Master, Israel)

[I-14]

High-Level

Innovative Solutions using Non-Linear S-Field Models and Combined

Effects

Prakash

R. Apte (Indian Institute of Technology at Bombay, India)

[I-15]

Applying

TRIZ

to Endodontic Tool Design

* Ellen

Domb (PQR Group, USA) and Joh "Jack" Jacklich (Special Products,

Inc., USA)

[TRIZ Journal, Dec. 2003: http://www.triz-journal.com/archives/2003/12/b/02.pdf]

[I-16]

Differentiating

the role of TRIZ in sustainable and disruptive innovation process

Pavel

Livotov (TriSolver Group Europe, Germany)

[I-17]

Fast

Software by TRIZ

Michael

Schlueter (Philips Semiconductors GmbH, Germany)

[II-3]

Keynote

Speech: TRIZ - past, present and future

Vladimir Petrov (TRIZ Master, Israel)

[II-4]

Innovation

process as a key to the market success in the engine manufacturing

business

Thomas Novacek (MTU Aero Engines, Germany)

[II-5]

About

non technical barriers preventing efficient TRIZ integration into

organisations

* Denis Cavallucci, David Oget, Michel

Sontag,

and Nathalie Gartiser (INSA Strasbourg, France)

[II-6]

Vehicle

soundproofing: Improved door seal

* Dominique Benoit and Chris Rhodes

(ArvinMeritor,

France)

[II-7]

Levels

of TRIZ support for the innovation and problem solving projects in the

automotive industry

Dennis

Murnikow (TriSolver Group Germany, Germany)

[II-8]

TRIZ

cases study in Volkswagen of Mexico

Edgardo

Cordova Lopez (Benemerita Universidad Autonoma de Puebla, Mexico)

[II-9]

Total

Product/Process Development System Where Six Sigma Meets TRIZ and QFD

Michael

S. Slocum (Breakthrough Management Group, USA)

[II-10]

Innovative

process chain optimization - Utilizing the tools of TRIZ and TOC for

manufacturing

Tilo Pfeifer and * Martine Tillmann

(Fraunhofer

Institute for Production Technology, Germany)

[II-11]

Constraint-dominated

breakthrough innovation in a manufacturing process situation (A case

study

from the photographic paper manufacture industry)

Ian

Mitchell (Ilford Imaging UK Ltd., UK) and * Darrell

Mann (CREAX nv, Belgium)

[II-12]

Towards

a management of problems formulation within the framework of lean

manufacturing

implementation

Zahir

Messaoudene (INSA Strasbourg, France)

[II-13]

Solving

technical problems in manufacturing processes by using embedded-TRIZ

Jan

C. Aurich and * Karsten Jenke

(University

of Kaiserslautern, Germany)

[II-14]

Applying

the TRIZ principles of technological evolution to customer requirement

based vehicle concepts - Experience report -

* Eckhard Schueler-Hainsch and Christine

Ahrend

(DaimlerChrysler AG, Germany)

[II-15]

Integrated

qualitative and quantitative invention analysis - A first look

Barry

Winkless (CREAX, Ireland) [presented by Darrell Mann

(CREAX,

UK)]

[II-16]

Observing

the development trends of glass moulds using the laws of technical

system

evolution

* Pavel Jirman (Tech. Univ. of Liberec,

Czech

Rep.), Bohuslav Busov (Tech. Univ. of Brno, Czech Rep.), and Alexander

Skuratovich (TRIZ consultant, Belarus)

[II-17]

TRIZ

experience at Huchinson

Nicolas

Gombert (Hutchinson, France)

[II-18]

TRIZ

based patent analysis for lighting electronics

Siegfried

Luger (Luger Reseaarch, Austria)

[II-19]

TRIZ-based

technology intelligence

Markus

Grawatsch (Fraunhofer Institute for Production Technology,

Germany)

[II-20]

Peculiarities

of structural and functional analysis of forecasted engineering systems

Peter

Chuksin (LG Electronics, South Korea)

[II-21]

Using

TRIZ to Create Innovative Business Models and Products

Atsuko

Ishida (Hitachi, Japan)

[TRIZ Journal, Dec. 2003: http://www.triz-journal.com/archives/2003/12/e/05.pdf

]

[II-22]

Onthe

question of the generating typical solutions

-- Alla

Nesterenko (Academy of educator's retaining and upgrading,

Russia)

[II-23]

TRIZ

for people: psychological aspects

Nelly

Kazyreva (Belarus-TRIZ, Belarus)

[II-24]

USIT

approach in Japan for simpler and powerful process of creative problem

solving in TRIZ

Toru

Nakagawa (Osaka Gakuin Univ., Japan)

-- orally presented during the poster session.

["TRIZ Home Page in Japan", Posted on Dec. 11, 2003

]

| ETRIA Web site | Personal Report ETRIA2001 | Personal Report ETRIACon2002 | TRIZCON2003 | Nakagawa's talk | Japanese page |

Last updated on Dec. 17, 2003. Access point: Editor: nakagawa@utc.osaka-gu.ac.jp