The 5th ETRIA "TRIZ Future 2005" Conference

(Held at Graz, Austria, on Nov. 16-18, 2005)

Toru Nakagawa (Osaka Gakuin Univ., Japan),

Dec. 29, 2005

[Posted on Jan. 13, 2006]

Editor's Note (Toru Nakagawa, Dec. 29, 2005)

This is a personal report of ETRIA TRIZ Future 2005 Conference held in id November (See ETRIA Official Web site

). This year the Conference was held in Graz, Austria, with 130 participants. It was announced that 70 abstracts were submitted, while 3 Keynotes, 46 Full papers, and 9 Posters are published in the Proceedings. Oral presentations of the papers were carried out in two tracks, for the first time in ETRIA conference. All these numbers show a steady growth of interests in TRIZ and its outputs in Europe and around the world. We wish to thank the Organizers and Sponsors of the Conference, especially Dr. Juergen Jantschgi, University of Leoben.

For me to write a 'Personal Report' (or a personal review) of a big TRIZ conference which I participated in has already become a tradition. Writing reviews and posting them publicly are difficult and delicate jobs, which wise people dare not to volunteer to do and talented people are always too busy to do so. I started this job in 1998 for the purpose of introducing TRIZ activities around the world to Japanese TRIZ community in Japanese, and since 2001 I have started to write them in English in response to requests from overseas readers. The increase in number and in extension of the conference papers makes this job take longer time. This year at the Closing Session in Graz, Denis Cavallucci, the President of ETRIA, asked me to write the 'Personal Report' again and the people applauded, to my surprise; so I promised to 'try to do my best'. As a matter of fact, reading (almost) all the conference papers carefully and writing a review of them are most fruitful for myself to understand TRIZ and its future; that's probably why I have been able to continue this job.

I assume that readers want to learn the current state and the future of TRIZ described in the conference papers as summarized not in official words but through my personal views. Please note again that this 'Personal Report' is written from my personal point of view, even though I am trying to do my best to understand the authors' points correctly and to describe things in fair ways. Particularly, the paragraphs (or sentenses) starting with '***' and the inserts enclosed in [ ] show my personal impressions and opinions. If you (especially the authors of the conference papers) find any mistake or misunderstanding in this report, please notify me via email. It is much desirable for readers to read the original papers and other persons' reviews. You should watch ETRIA Web site

, authors' individual sites, the TRIZ Journal

, and this "TRIZ Home Page in Japan"

for future postings.

I wish to thank ETRIA, Dr. Juergen Jantschgi, and the authors for their allowing me to cite their figures, especially the original figures in full color, in this report.

| Conference Name: | ETRIA World Conference: TRIZ Future 2005 |

| Main Theme: | "Bridging East and West" |

| Date: | Nov. 16 (Wed.) - 18 (Fri.), 2005 |

| Place: | Stadt-halle, Graz, Austria |

| Held by: | European TRIZ Association (ETRIA) |

| Organized by: | University of Leoben (Industrial Liaison Department, http://www.ausseninstitut-leoben.at/), |

| Participants: | 130 people from 23 countries |

| Outline of the Agenda: | 2 Tutorial Lectures, 3 Keynote Speeches, 1 Panel Discussion, 38 Presentations in double tracks, and 9 Poster presentations; from 9:30 through 18:00 for the three days. |

Overview:

This is the Fifth World Conference on TRIZ organized by ETRIA (European TRIZ Association). The first one was held at the University of Bath, UK (See my Personal Report of ETRIA TFC 2001 ), the second at ENSAIS Strasbourg, France (ETRIA TFC 2002

), the third at RUTH University, Aachen in Germany (ETRIA TFC 2003

), and the fourth at Florence, Italy (ETRIA TFC 2004

). This year the Conference was held at a modern convention center 'Stadt-halle' in the city of Graz, Austria. Graz is the second largest city of Austria and has the charming old city center registered as one of the World Heritage since 1999. University of Leoben, especially Dr. Juergen Jantschgi of Industrial Liaison Department, is the core of the organization.

The total number of participants was announced to be 130 according to the organizing committee. Participants came from 23 countries. [Statistics may be seen somewhere else.]. This number is the largest of the ETRIA conferences.

Tutorial lectures were given by Ellen Domb on TRIZ Basics and by Sergei Ikovenko on TRIZ Advanced for 135 minutes in the morning of the first day. The symposium started after lunch with Opening addresses, Keynote Speech by Laurent Lelait, and then 11 presentations in double tracks. On the second day, we had a Keynote Speech by Larry Smith in the morning and a Panel Discussion in the afternoon by Mark Barkan (President of MATRIZ), Larry Smith (President of Altshulller Institute, USA), and Denis Cavallucci (President of ETRIA). 15 Presentations were carried out in double tracks. On the third day, a Keynote Speech by Simon Litwin and 12 oral presentations were given. Each oral presentation is scheduled to be 30 minutes including discussions; but most of them seem to have taken 5 to 10 minutes longer. There were several changes in the agenda due to the absence of presenters from Ukraine, Israel, China (due to Visa Problems), and Iran; they fortunately served to make the presentation schedule adaptable to the prolonged discussions. Posters were displayed at the hall for the full three days.

The Proceedings was published in an excellently bound book of 554 pages. The list of the papers and posters published in the Proceedings are shown at the end of this page. In the present review the papers are referred with the numbers in this list as shown in [ ]. It was reported that 70 abstracts were submitted to the Conference. The Committee of Approval (organized by Denis Cavallucci, Gaetano Cascini, Markus Grawatsch, Darrell Mann, Pavel Livotov, Nikolai Khomenko, and Valeri Souchkov) selected 50 of them for full papers and others for optional poster presentations.

Topics of the presentations cover a wide range. The sessions were arranged partially in accordance with the topics but not always. In the present report, I will review the papers in the following categories:

(A) Keynote Speeches and Related Works

(B) Promotion of TRIZ

(C) TRIZ Methods for Problem Solving

(D) Case Studies of TRIZ for Problem Solving

(E) TRIZ Methods for Strategic Development of New Products and Technology Prediction

(F) Extension of TRIZ Application Fields in Technologies

(G) Integration of TRIZ with Relevant Methods

(H) TRIZ and Patents and Knowledge Management

(I) TRIZ and Education

(J) Poster Presentations and No-Presentation Papers

Some Concluding Remarks are described after these reviews.

Note: Tutorials are not reviewed here. Keynote by Lelait, Panel Discussion, and Closing Remarks by Denis Cavallucci are not reviewed here, because they may be reported officially (and because I am not good at taking notes of spoken discussions). Presentations I attended at are marked with * in the table of agenda. During the Conference I was in a bad condition due to a cold; so I missed two presentations in the morning of the 2nd day.

Agenda of ETRIA TFC 2005 [as actually performed]

Nov. 16, 2005 (Wed.)

Morning |

Tutorial: TRIZ Basics |

Tutorial: TRIZ Advanced Sergei Ikovenko * |

Afternoon |

Opening TRIZ Future 2005 | |

| Keynote: Organizing and Managing TRIZ Potentials to Address Research Problems Laurent Lelait [A1] * |

||

Afternoon 14:30- |

Acceleration of TRIZ Propagation in Samsung Electronics Jung-Hyeon Kim et al. [1] * |

On the Possibility of TRIZ Techniques in MOT-Education Program at the Company Manabu Sawaguchi [5] |

| From A Pure Production Plant to the World Leading Centre of Household Compressor Design Meinhard Falch et al. [2] * |

Innovation and Knowledge Management Guillermo Cortes Robles et al. [6] |

|

| Trends of Evolution of Engineering Systems Help Designers to Develop Next Generation Products Len Malinin [9] |

||

Afternoon 16:30- |

Reviewing an Innovation Project for a New Electrical Terminal Siegfried Luger et al. [7] |

Back to Creatability Klaus-Juergen Uhrner [3] * |

| TRIZ Development of Robotic Vacuum Cleaner Valery Krasnoslobodtsev et al. [8] * |

TRIZ and ExpertPRIZ Type AI Software in Engineering and Education Tiit Tiidemann et al. [13] |

|

| Directed Variation: Solving Conflicts in TRIZ Simon Dewulf et al. [10] * |

The Case of Simplification -- Rapid POKA YOKE Development Using TRIZ Sergei Ikovenko et al. [14] |

|

Evening |

Welcome Buffet and Poster Presentation | |

| City Walking Tour - Graz | ||

Nov. 17, 2005 (Thu.)

| Morning 9:15-10:00 |

Keynote: Growing TRIZ in the 21st Century Larry Smith [A2] |

|

Morning 10:30-12:30 |

Progress and Ideality Avraam Seredinski et al. [15] |

Mutual Compensation of TRIZ and Axiomatic Design Kyeong Won Lee et al. [19] |

| Business to Technology -- New Stage of TRIZ Development Simon Litvin [16] * |

As the "Smart Materials" Can Help the Inventor Alexander Kynin et al.[22] |

|

| On Innovation Timing Darrell Mann [17] * |

Problems of Forecast Dmitry Kucharavy et al.[18] |

|

| Afternoon 13:45-14:45 |

Panel Discussion |

|

Afternoon 15:00- |

Mastering Strategic Innovations contra Location Crisis: WOIS Hansjuergen Linde, Gunther Herr et al. [30] * |

Success Through Integration of TRIZ, DFSS and Strategic Management Johannes Pfister [24] |

| R&D Process Aided by Computational Analysis and TRIZ in LS-Cable; and Case Study Jeong-Ho Kim et al [23] * |

Boolean Combination and TRIZ Criteria: A Practical Application of a Patent-Commercial-Database Nani Roberto [27] |

|

Afternoon 16:30- |

How to Deal with Cost-Related Issues in TRIZ Ellen Domb [25] * |

New Search and Problem-Solving TRIZ Tool: Methodology for Action & Problem Oriented Search (APOS) Boris Axelrod [28] |

| Modularity vs Product Performance: Contradictions and Solutions Gaetano Cascini et al. [29] |

Software Engineering and TRIZ (2): Step-wise Refinement and the Jackson Method Reviewed with TRIZ Toru Nakagawa [32] * |

|

| Analysis and Representation of Information in Forecasting Peter Chuksin et al. [31] |

||

| Evening | Poster Presentations, Open Space Discussion | |

| Dinner -- Reception by Land of Styria and City of Graz * | ||

Nov. 18, 2005 (Fri.)

Morning |

Keynote: TRIZ Readings -- Altshuller's Tradition Continuation |

|

Morning 10:45-12:45 |

Theoretical and Practical Aspects of Developing TRIZ-Based Software Systems Alla Zusman et al. [35] * |

General Issues of Teaching TRIZ at University Victor Berdonosov et al. [38] |

| TRIZ Application for Patent Strategies Development Sergei Ikovenko et al. [36] * |

Utilization of TRIZ to Propose Innovative Solutions for Higher Education and Research Problems in Mexico Edgardo Cordova Lopez et al. [44] |

|

| Technology Intelligence: Defining the Potential of Emerging Technologies Markus Wellensiek et al. [37] |

The OTSM-TRIZ Based System of Models for Teaching Students to Organize Their Thinking Alla Nesterenko [40] * |

|

Afternoon 14:00- |

Root Conflict Analysis (RCA+): Structuring and Visualization of Contradictions Valeri Souchkov [41] * |

Project European SUPPORT Wolfgang Schabereiter [33] |

| CAI-Based Innovation Management at ALVEO AG Peter Schweizer et al. [39] |

OTSM-TRIZ Tools in the Preschool Education: What and For What to Learn? Anna Korzun [45] * |

|

| Applied Methodical Innovation Management in the Expert Group "Crea(c)tor" Lorenz Meierhofer [42] * |

Using OTSM-TRIZ in Learning and Teaching English Foreign Language: An Epistemology Reflection David Oget et al. [46] |

|

Afternoon |

Final Discussion |

|

| 17:30-18:30 | Meeting ETRIA-Board * | |

(A) Keynote Speech and Related Works

The first of three keynote speeches was "Organizing and Managing TRIZ Potentials to Address Research Problems" by Laurent Lelait [A1]. Please forgive me but I cannot summarize it because of no handouts.

The second Keynote speech was "Growing TRIZ in the 21st Century" by Larry Smith (President of the Altshuller Institute) [A2]. Based on his decade-long case studies of promoting TRIZ in Ford, he pointed out serious needs of understanding and addressing the inhibitors of TRIZ initiatives. The most basic fact, he pointed out, is that TRIZ operates on a higher level of thinking, as shown schematically in the following figure.

The four domains are taken from Nam Suh's scheme in Axiomatic Design, while the three levels of thinking are from Peter Senge's model. 'Event-level thinking' is actually direct response to problems when they happened. 'Pattern-level thinking' involves managing the process by which we do things, so that trends in the process may be corrected before unpleasant events occur. 'Structure-level thinking', on the other hand, deals with the fundamental architecture of a system and may be used to fix problems at the pattern level or at the event level. TRIZ and Axiomatic Design work at the 'Structure level'. Such higher level thinking makes TRIZ more powerful and at the same time more difficult to understand. Thus, the author proposes initiatives to find a better way to teach TRIZ to students/engineers, a better way to communicate with management, and a way to bring TRIZ to all the children of the world.

*** A minor remark by the author attracted my attention: "TRIZ started at Ford in 1993 with many memorable projects, some involving TRIZ Masters. .... In addition, Structured Inventive Thinking (SIT) [i.e., USIT] was introduced at Ford, and over a thousand engineers were trained and worked on problems with SIT. Along with success, these case studies also generated: ... Resistance from some who treated SIT as a "religion" and actively lobbied with management that no other form of TRIZ was needed or desired." And as a part of conclusion, the author writes: "Think collaboratively rather than competitively. Grow the TRIZ 'pie' for everyone." In this context I remember that Ed Sickafus, the originator of USIT at Ford, once claimed "USIT is neither a sort of nor a part of TRIZ", and that Victor Fey, a TRIZ Master, completely denied (in his ETRIA 2004 Keynote speech ) USIT as a form of TRIZ. Thus I can imagine the unfortunate severe struggles among the two parties.

*** When Nakagawa introduced USIT into Japan in 1999, he wrote that "... As I understand recently, the most important topic in the modern development of TRIZ is to adapt it to much wider technologists in the world. ... With this understanding, I feel it quite natural to treat USIT as a family member of the modernized TRIZ methodology." This has been the spirit of the USIT approach in Japan for these nearly 7 years. All the papers and articles I have written so far are related to this motive, and they actually contributed, I believe, to extract best parts of TRIZ and to unify them into the simpler framework of USIT.

The third of Keynote speech was given by Simon Litvin (TRIZ Master, GEN3 Partners, USA) [A3] with the title of "TRIZ Readings -- Altshuller's Tradition Continuation". This title needs a special explanation: The word 'TRIZ Readings' here does not mean TRIZ references but a special workshop meeting held by Altshuller in 1980. He gathered 20 leading TRIZ specialists in Petrozavodsk and they discussed for three days only the most important issue "How to further TRIZ development; mainly ARIZ". The outcome of the workshop was a significant modernization of ARIZ, resulting in the appearance of ARIZ-82 and later ARIZ-85B, i.e. the final version developed by Altshuller. In July 2005, a workshop having the same intention was held in the suburbs of Saint Petersburg with the initiative of Simon Litvin (USA), Michael Rubin (Russia), and Vladimir Petrov (Israel). 20 (+ alpha) TRIZ Masters (and TRIZ specialists) gathered and discussed for one full day, giving their own position papers on what are the main directions of TRIZ development, the author reported. In the Keynote Simon Litvin reported his personal view, not a representative/common view of the workshop participants, in the following points:.

Talking about TRIZ in the technology, Litvin states: "The main problem of TRIZ is that the methodology itself and the practices of its application have been in a state of stagnation for a long time." Then he pointed out the following problems that hinder TRIZ development and acceptance:

*** There were a number of discussions on this topic from the floor. It was a great pleasure for me to hear that the workshop of TRIZ Masters anonymously agreed to further develop or improve TRIZ itself, in contrast to the Keynote speech by a TRIZ Master Victor Fey last year claiming "Don't touch TRIZ!". Many presentations in the present ETRIA conference are actually trying to solve the problems listed here.

*** In relation to the last item above, Litvin mentioned an approach with a team of TRIZ professionals. In Japanese practices, however, a joint team of engineers and a TRIZ/USIT expert as the coordinator works fine. This approach is quite natural because we know that guiding engineers in their thinking process in TRIZ/USIT is easier and more effective than trying to find and build useful solutions by ourselves by using TRIZ/USIT tools without having professional capability in the problem fields.

Simon Litvin presented another paper [16] to discuss one of the most important issue listed above; his title is "Business to Technology - New Stage of TRIZ Development". He says: "In industry, the major objects are not engineering systems (products and technological processes), but companies. ... One reason TRIZ is still not well accepted in the industrial community is that it doesn't have specific tools to address business challenges (rather than technical challenges)." He has shown that GEN3 Partners have developed over the last few years a set of TRIZ-based tools to build the bridge between business challenges and technical problems. They include: TRIZ Benchmarking; TRIZ Core Competence Audit; Opportunity Assessment; Joint Analysis of Market Trends and Trends of Engineering System Evolution; and Main Parameters of Value (MPV) Assessment.

The MPV approach is very impressive to me. He defines Innovation as 'significant improvement along a main parameter of customer value', and then defines different levels of MPV (Main Parameters of Values): MPV's at the strategic level for business are the product attributes that define customer behavior on the market. And MPV's at the functional level (i.e. the top level for engineering) are objective technical parameters that are responsible for the strategic MPV's. He notices that traditional market-recognized parameters (like performance, convenience, safety, styling, indulgence, cost, etc.) are too general and are not instrumental for innovation. (In this relation, see the presentation by Ellen Domb [25] on the 'Cost-related issues'.) The following slide shows a wonderful case study of the MPV approach (by courtesy of the author). [The paper in the Proceedings are only two pages of outline. We wish the author publish a full paper as soon as possible.]

(B) Promotion of TRIZ

A presentation from Korea seems to have given the most successful case of promoting TRIZ in industry. Jung-Hyeon Kim, Jun-Young Lee, and Sung-Wook Kang [1] reported on "The Acceleration of TRIZ Propagation in Samsung Electronics".

*** Participants of ETRIA TFCs and TRIZCONs have noticed that Korea has been sending several (11 this time) engineers and presenting a few (5 this time) papers in these conferences every time (including some presented by Russian TRIZ experts working or worked for Korean companies). Most papers presented so far from Korea dealt with case studies and TRIZ tools in individual companies, and hence they might have failed in presenting the overall TRIZ activities in Korea.

*** TRIZ was introduced into Korea around 1998 with a rather slow pace, but the pace was much accelerated around 2001 with the employment of multiple TRIZ experts from Belarus and Russia in Samsung and LG. Achievement of the TRIZ team especially in Samsung Advanced Institute of Technology (SAIT) was recognized by the top executive. Thus the executives of Samsung group companies promoted TRIZ as an innovative methodology in the framework of Six-Sigma movement. Samsung TRIZ Association (STA) was formed in 2003 to enhance the TRIZ promotion and education in Samsung group companies, including SAIT, Samsung Electronics, Samsung SDI, and Samsung Electro-Mechanics. The Samsung group companies are now the industry where TRIZ has been promoted and utilized most aggressively and successfully in the world.

The way of implementing TRIZ in Samsung is illustrated in the following flowchart set up by STA.

The authors of [1] state that Samsung Electronics started Introducing TRIZ in 2001 [see the case study presentation [8] by Krasnoslobodtsev, who guided the TRIZ team in this initial stage] and is now at the beginning of the Acceleration Stage in the above figure. More than 70 TRIZ projects were carried out in 2004, and over 90 in 2005. Samsung Electronics has made much efforts for training engineers in TRIZ. They have 3 courses in TRIZ: Basic Course of 40 hours, Application course of 40 hours, and the Certificate Course of 40 hours lecture and actual problem solving. They already have over 90 TRIZ specialists who were trained at Level 2 of MATRIZ Certification with applying TRIZ to their own projects. They say the company have started training 4000 new employees this year in the Creative Thinking Course based on TRIZ. For providing opportunities of TRIZ education to so many employees, they have built on-line training materials in TRIZ. The material are going to be available for all the Samsung-group companies.

*** The activities of TRIZ and Six-Sigma in Korea are really remarkable! Hyo June Kim, the TRIZ pioneering leader in SAIT, told me that Samsung Electronics are introducing TRIZ really aggressively even in his eyes.

Meinhard Falch and Walter Brabek (ACC Austria GmbH, Austria) [2] reported on their activities in an Austrian company, with the title: "From A Pure Production Plant to the World Leading Centre of Household Compressor Design". They implement TRIZ methodology in the framework of Project Management of R&D, as shown in the following figure.

The TRIZ tools are implemented in the project management in the forms relatively easy to handle; for example 'Innovation Checklist (ICL)' and 'Resource Checklist (RCL)' are used together with Patent Analysis and Internet Investigation, at the Situation Analysis phase of the Target Definition Stage. Then in the Target Definition phase, they use the S-curve analysis and the concept of Ideal Final Result. Further in the Stage of Design of Variants, they use the Trends of Evolution with the help of the 'CREAX Innovation Suite' software tool. The authors say that the recent development of ACC Austria is a story of success based on innovation, with the methodology shown in the above figure.

The presentation by Klaus-Juergen Uhrner (KACO GmbH, Germany) [3] is a really unexpected demonstration of the usage of TRIZ, with a somewhat peculiar title: "Back to Creatability". He is an engineer and a self-taught TRIZ user since 1996. He recently wanted to convince a number of executives of Austrian SME's with the usefulness of TRIZ. He wanted to demonstrate the effects of TRIZ qualitatively, quantitatively, and from the perspective of personal capability. Since he could not find such a document, he decided to analyze the existing patent data of his own company. The following three figures represent the real cases of analyzing 164 patents obtained for these 30 years by his company, KACO GmbH.

The first figure shows all the KACO's inventions (or filed patents) plotted against the year. Each circle stands for a patent, marked with the identification number. Three engineers who are named 'Red', 'Yellow', and 'Green', are of special interest in this analysis, and their patents are colored accordingly, while other engineers' patents in gray. The starting time of the three engineers are shown at the top of the figure. In 1996, the 'Red' engineer started using TRIZ, and then in 2000 four other engineers including 'Yellow' and 'Green' joined in using TRIZ. The circles colored in white stand for the TRIZ-based inventions. As shown by the dotted lines in the figure, the average number of inventions per year was 3.0 without influence of TRIZ, while it has become 9.7 with the influence of TRIZ. Thus the effect of TRIZ usage is clear here quantitatively, showing about 3 times in number of inventions.

The quality of the patents/inventions were evaluated by use of the 'Altshuller's Criteria of Levels of Inventions' with a modification of adding some commercial and strategic aspects. The figure below shows the Innovation Levels of all the 164 KACO inventions.

This figure shows that most of the inventions in the old era without TRIZ were lower than Level 3. Nevertheless, three very high-level inventions were created by the three engineers at their very early stage of working (i.e. after about 1.5 years of training) in this field, and they were of utmost importance for the company. Though many more inventions were made by the three engineers afterwards, the level of them were not so high. "As the inventor becomes more and more an expert, he loses his innocence of thinking, or with other words, he is driven by Psychological Inertia."

After introducing TRIZ, the levels of the inventions changed dramatically as shown in the upper right corner of the above figure. There appeared a lot of inventions with Level 4 or higher, and the average level of inventions has become as high as 3.4 after the introduction of TRIZ in contrast to 2.4 before the introduction. It is also remarkable that the three engineers, 'Red', 'Yellow', and 'Green', gained back (or actually even higher degree of) capability of creating inventions. (Thus comes the title of this presentation, "Back to Creatability".)

Another figure shown below distinguishes the inventions/patents which have actually solved some contradictions (white symbols) from those which solved non contradictions (black circles). It is noticed that Level 2.5 is the gray boundary zone. Inventions at Level 2 or lower are the solutions without solving contradictions, while those at Level 3 or higher are the solutions having solved some contradictions. It is clear that the introduction of TRIZ helped to (identify and) solve contradictions. Since the inventors obtained the experiences and capability of solving contradictions, they have become (and will stay to be) better inventors than they have ever been.

*** This presentation is indeed valuable for the TRIZ community in the world, as it is a real data of effects of TRIZ in the quantitative, qualitative, and personal capability aspects. We eagerly wish that engineers and business managers who do not study TRIZ yet learn this case without prejudice. Similar analysis can be carried out in various companies/countries which already have some history of TRIZ usage.

*** There were some discussions from the floor. Somebody asked: "So, looking at your data, the people in your company and executives of SME's around you have been convinced with the TRIZ effects?" The answer by the author was unexpected for me: "Not so much. Some people seem to have some unpleasant feeling to my presentation of the results." Such reactions by human are very sad. The reactions may have been induced partly by the fact that the analyis was done by the author who is in fact the 'Red' engineer, as you can deduct from the data presented in the paper. For overcoming such a reaction, and for making Uhrner's demonstration as a common property of the TRIZ community, it should be helpful to verify Uhrner's work in the TRIZ community. According to the private communications with the author, however, it is found that the inventions for the last several years (i.e. most part after the introduction of TRIZ) are mostly not publicized yet. Hence at moment we cannot verify Uhrner's data directly. But since the scheme of analysis is clearly shown, it should be possible in every organization to analyze the historically accumudated data of their own inventions in an objective manner. Anyway, this Uhrner's paper is the utmost fruit in the present conference, I believe.

Wolfgang Schabereiter (University of Leoben, Austria) [33] reported on their activities of "Project European SUPPORT". Its abstract says:

Strengthening the innovation power in European companies as well as encouraging sustainable development are two of the main future goals of the EU (see Lisbon goals, European Council 2000). In the last three years the Industrial Liaison Department of the University of Leoben, Austria, was engaged in several projects both on the European, national and the regional level to encourage companies to learn and practice innovation- and creativity-tools in order to strengthen their creativity potential. The idea of this paper is to show mainly the European SUPPORT in which the TRIZ methodology plays a major part.

Being its fourth year, the SUPPORT project already established a training course consisting of seven modules: i.e.,

1. Introduction module: Innovation/creativity & sustainable development,

2. Aspects of Cleaner Production for products and processes,

3. TRIZ-tools for problem analysis (innovation checklist, ideality, functional analysis)

4. TRIZ-tools for idea generation I (innovative principles and contradictions)

5. TRIZ-tools for idea generation II (S-curves, evolution lines)

6. Tools for idea evaluation,

7. Project management

Course materials for participants (paper and CD-ROM) and for trainers are available, together with video sequences of the whole project. The Project held the 'Train the Trainer Course' and a 'MATRIZ Level 2 Course' for training the trainers coming from each participating partner countries. Trials to transfer the innovation methodology to universities/institutions and to industrial user companies are carried out actively.

Lorenz Meierhofer (Future Management, Austria) [42] gave a unique presentation "Applied Methodical Innovation Management in the Expert Group 'Crea(c)tor'". [(c) stands for 'c' in a circle.] 'TRIZ Center Austria' was formed in December 2002 as an independently operating club of researchers, users, and consultants interested in TRIZ and attracted dozens of active members. How to spread and enhance innovation methods in practice has been a problem issue among them. In fall 2004, they obtained an idea of forming a stable circle of interested TRIZ experts who are ready to work on specific demands and problems. The circle is named 'Crea(c)tor'. It is defined as a loosely coupled network of innovation experts, working together in flexible teams for specific tasks, as the subgroups in 'TRIZ Center Austria'. It works in the following way:

Whenever a properly prepared proposal for a topic comes in, a call for members is issued. Every member of 'TRIZ Center Austria' who has time and interest in the matter is welcome. However, after the team formed, joining it is only possible for those specifically invited to do so by the team. (When a topic fails to interest people and no team of proper size is formed, the proposal is automatically rejected.) Every team works independently on a topic. A client (e.g. a company) who wants a team to work on a specific task would sign a contract with every single team member. A few different types of Business Model were made for the Crea(c)tor, including paying a fixed problem fee that covers all work necessary to solve the problem, paying a fee per workshop, and sharing the intellectual property rights/ cost advantages/ revenues. They intend to cover unavoidable expenses and to reward the participants for their engagement. Workshops of the 'Crea(c)tor' are active, pleasant, and fruitful for the expert members. Due to the good knowledge of innovation methods by all team members, switching and mixing methods is extensively done leading to a less strict workshop design that highly supports the creative potential. This generates an unstopped flow of creativity leading to extraordinary problem definitions and solution ideas.

*** This is a very interesting way of performing fruitful workshops among innovation experts. It can be valuable opportunities for experts to communicate and exchange their methods, experiences, and knowledge of innovation methods. Similar style of informal workshops can be done among voluntary engineer circles in a company. In Nakagawa's 2-day USIT Training Seminars, real brought-in problems are solved in a more-or-less similar manner by the participants; only difference is that they need a guidance lecture of the methodology at each stage of problem solving. I also notice that in Darrell Mann's textbook "Hands-on Systematic Innovation" several case studies seem to be performed in exactly the 'Crea(c)tor' way for illustrating TRIZ-tools.

(C) TRIZ Methods for Problem Solving

Ellen Domb (PQR Group & Editor of the TRIZ Journal, USA) [25] gave an important presentation with the title of "How to Deal with Cost-Related Issues in TRIZ". The top part of her Abstract clearly states the importance and difficulty of this issue:

"People learning TRIZ frequently have difficulty with the issue of cost, since cost reduction is a pervasive theme throughout industry, yet many techniques of TRIZ do not deal with it explicitly. But, if beginners don't have success in applying TRIZ to the first problem that they try, they will frequently abandon efforts to learn the TRIZ system. ... "

For discussing the cost issue, we need to understand the wide variety of causes for the cost. They are:

1. Cost of raw materials

2. Cost of labor (Production of parts, Assembly of final product (or Deliver of service), Testing, and After-sale support)

3. Cost of transportation (Transportation of raw materials, parts, and finished products (or for delivering services))

4. Management costs, which include:

4a. Management of suppliers,

4b. Management of the organization (engineering, design, production, procurement, service, support, sales, marketing, employee training, human resource costs, etc.)

4c. Management of customer relationships,

4d. Cost of poor quality (labor costs for testing analysis, and rework; materials costs for replacement of bad raw materials or parts; transportation costs for the replacement; warrantee costs for replacement of bad products or repairing the effects of bad services; and the cost of damage done to the company's reputation with the customer.)

Thus, TRIZ experts would try to analyze the system with wider perspectives, using the System Operator (i.e. 9-windows method), Ideal Final Result, etc., for revealing most significant causes of the present cost problem. However, the author says, TRIZ beginners want to use the TRIZ tools they have learned at the basic seminars for solving their own problem of cost issues. So we, TRIZ leaders, have to be prepared for guiding the beginners well in solving cost-related issues with ordinary Beginner TRIZ tools, such as Functional analysis, the Contradiction Matrix, and the Forty Principles. For this purpose, Ellen Domb proposes the following scheme as "The Beginners' Flowchart for Cost Problems":

*** The author gives a number of instructions for the beginners to use the standard beginner TRIZ tools especially on the cost problems. Skipping those details, I would like to sum up this paper by quoting the last part of the author's Conclusion:

"... The growth of TRIZ depends on the ability of TRIZ experts to make it easy for TRIZ beginners to have early successes, so that the beginners will decide to do the work that will increase their knowledge and capability. This simplified TRIZ problem solving method is proposed as one way to give beginners that experience of success."

Valeri Souchkov (ICG Training & Consulting, The Netherlands) [41] also gave another nice instructive presentation with the title : "Root Conflict Analysis (RCA+): Structuring and Visualization of Contradictions". The author points out the difficulty in TRIZ by saying: "Although TRIZ provided reliable techniques to solve inventive problems, it always lacked clear and structured way to manage complex problem situations. ... Without good understanding of underlying causes we risk to invest considerable efforts to solving a wrong problem." Thus he was looking for general methods to analyze complex situations especially in cause-effect relationships and contradictions. He once observed the TRIZ experts of the Dutch company DSM use the Root Cause Analysis (RCA) technique and found it closely related to the TRIZ philosophy. Then he developed the RCA+ method presented in this paper and extensively tested it during last three years of numerous applications in business and technology and has proven its effectiveness, the author says.

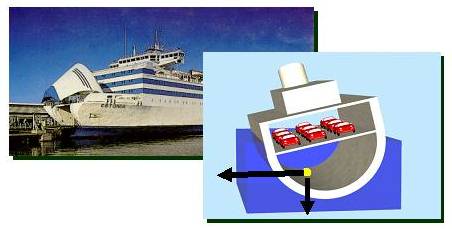

The RCA+ Method is demonstrated well with a study of the case of the ferry 'Estonia' accident. In 1994, an accident during the sea ride of the ferry 'Estonia' had happened, and about 850 people lost their lives. The accident was caused by the bow door which suddenly opened during the ride and sea water poured to the cargo deck. The amount of water was not enough to make the ferry sink, but water movement caused the loss of stability of the ferry which resulted in capsizing and sinking. See the figure below:

For this case, the RCA+ Diagram is drawn as shown in the figure below. The author writes: "The essence of the 'Root Conflict Analysis' (RCA+) method is to identify and describe those causal chains of causes and effects that contribute to an array of contradictions composing a problem. The cause-effect diagrams are represented as trees with nodes standing for effects/causes. They are proposed to be built in a top-down manner, starting with a general negative effect and then moving downwards by describing a chain of causes that lead in the general negative effect until a specific conflict is reached. Both 'in-depth' and 'in-breadth' strategies should be explored."

In the figure, the minus marks in circles represent negative events (causes/effects). But some events are there for intending (or functioning) some positive events (with the + marks in circles), which are added in the figure to clarify the overall system situations. Thus in the RCA+ diagram, contradictions are revealed clearly. For example, at the right-bottom corner of the above diagram, we have the event 'Empty space in the cargo deck' having both positive and negative effects (and hence marked with +- in a circle). Here we can see two type of contradictions:

Technical Contradiction: "If we enables cargo storage by making empty space in the cargo deck, then we have a bad effect that water moves."

Physical contradiction: "The cargo deck should contain empty space to enable loading/uploading of bulky cargo and must not contain empty space in order to avoid movement of water during an accident."

This Physical contradiction can be solved with the Separation principle in time. Thus a new solution was generated smoothly, the author writes, i.e. "To deploy airbags near the ceiling of the cargo deck in case of emergency, in order to prevent the motion of water and to increase the floating ability of the ferry".

*** This diagrammatic method seems to be easy to construct and clear in logic and in visualization. The scheme of showing both Technical Contradictions and Physical Contradictions is nice for understanding them together, and it is also descirbed, I notice, by Larry Ball in his course material "Hierarchical TRIZ Algorithms" (see his series of lectures in the TRIZ Journal, 2005).

Boris Zlotin and Alla Zusman (Ideation International, USA) [35] gave a presentation "Theoretical and Practical Aspects of Developing TRIZ-Based Software Systems". This is a review paper of their activities in relation to TRIZ software development since mid-1980s in Kishinev and then in Ideation International. The focal point of their development has been how to make the 'analytical' aspects of TRIZ (in contrast the 'knowledge-base part' of TRIZ) easier and more effective to use with software tools. Their motive in this paper was also expressed in the first TRIZCON in 1999, I remember (see my 'Personal Report of TRIZCON99' posted in Japanese ), and published in their transaction "TRIZ in Progress". In Classical TRIZ there are a lot of tools in parallel, they say, as shown in the following figure:

The final (or current or target?) form of their development of the software tool in Ideation International intends to cover the whole range of the problem solving process, as shown in the following scheme:

The modules of the software in the above scheme 'should perform' the following functions, the authors say:

ISQ (Innovation Situation Questionnaire): Collection and reorganization of information about the situation and the system.

PF (Problem Formulator): Visualization and automated generation of a practically exhaustive set of directions for innovation (solutions).

System of Operators: Automated process of suggesting operators (recommendations) with statistically proven relevance to the selected directions for innovation and of prompting users for idea generation.

Concept development: Consolidation of ideas into concepts

Evaluation: Evaluation of obtained ideas and their enhancement using selected patterns of technological evolution.

*** I notice that in their TRIZCON99 paper (thus in IWB) the three modules of ISQ, PF, and Evaluation appeared and the 'System of Operators' was placed in parallel to all the Classical TRIZ tools. (Note that the stage of 'Concept development' does not appear in the figure above.) Thus the most important message of the present paper seems to be "the System of Operators is set to replace all the Classical TRIZ tools except some guide and reference to ARIZ". But unfortunately, this kind of conclusive message is not stated clearly in the present paper and the contents of neither 'the System of Operators' nor the guide are explained. The paper shows a link to their Web site for referring to a case study on Containment ring problem illustrating their problem solving process with their IWB (or its newly released version IWB 2005). Probably this is the only publicized information on their 'System of Operators' (except those in their commercial products). It is unfortunate that a 14-page paper by the leading TRIZ Masters contains no up-to-date scientific descriptions.

The paper [35] also discusses about the basic approaches for 'automation' (or 'support') of problem solving with software tools. The authors show two basic approaches [I dropped their metaphorical namings and expressions], claiming:

A: The search for a good solution through trials of variants; this approach is used in many methods of problem solving, the difference is in the ways of trials are made. Traditional approach taken in inventive problem solving (including traditional TRIZ).

B: Generating many potential directions and concepts, then rejecting some according to specified criteria. The authors' approach.

*** I think that this way of classifying (or contrasting) problem solving methods is not appropriate. Any problem solving method should have the functions (or activities) of generating a potential solution (i.e., a trial, a variant, a direction, a concept, or any other) and evaluating it (i.e., rejecting, pending for further consideration, using as a base for further improvement, taking as a potential candidate, taking as a final solution, etc.). The activities of generating potential solutions and evaluating them are often done in different sizes (in number of potential solutions) and in interleaved or repetitive manners.

*** The authors' approach, as far as I understand, is to analyze (i.e. search) the problem situations and causes and then to generate as many potential solutions automatically (or semi-automatically) with a software tool, and to let the inventors (or users) to reject poor ones at the process of evaluation. Thus they assume that the 'seemingly exhaustive' solution generation by the software tool (combined with human rejection process afterward) is better or more creative than any methodically-supported solution generation by human. I am very doubtful of their assumption. The analysis of the problem situations and causes done at the early stage is often much improved afterwards during the phases of analysis (e.g., function/attribute analysis, time & space analysis, ideal solution analysis, etc.) and solution generation. Thus, the initial analysis often does not get to the point and thus the seemingly exhaustive list of potential solutions does not include more desirable solutions. [For example, see my comment in 'TRIZCON2001 Personal Report' on 'Truck Fuel Tank Problem' reported by Clark and Zlotin.]

*** Another point I concern about is human psychology. A long series of short-time brainstormings for generating ideas to a list of tens or hundreds of automatically generated solution directions sounds not pleasant to me. Evaluation in the form of rejecting a lot of potential solutions seems to make the inventor think in the 'negative mode' (or in the 'Black Hat'). We know that new and innovative solution proposals usually have a lot of difficulties at first sight, and they are readily rejected by many engineers and managers. It should be important to keep the project team (of engineers, not TRIZ specialists) in much more positive and creative attitude.

Simon Dewulf and Vincent Theeten (CREAX, Belgium) [10] gave a presentation on "Directed Variation: Solving Conflicts in TRIZ". 'Directed Variation (DIVA)' is a concept of methodology implemented in their new software tool, with the slogan of 'So advanced, it is simple'. One of its key factors is the integration of innovation tools with language, the authors say. They have analyzed about 16000 US Patents of a month (Jan. 2005), and found 2000 unique nouns, 800 unique adjectives, and 700 unique verbs. They say: "Products are Nouns. But we are not interested in a noun or a product. We're interested in the difference, the variation of the product, the Adjective noun (e.g., not the toothbrush, but the hollow toothbrush, the flexible toothbrush, etc.). Adjectives define variations. These adjectives are related to functions, which are expressed in Verbs."

The first type of DIVA process is illustrated in the figure shown bellow. Concerning to the current product, a cube sugar in this example, its various properties are listed up first, e.g., solid, square, single taste, etc. Then each property is examined along its 'Property spectrum' (which corresponds to the TRIZ Trends of Evolution). For instance, the property 'solid' belongs to the Spectrum of 'State' (i.e., solid - liquid - gas - field), and can be varied into 'liquid' as the next stage in the Spectrum. The Spectrum (or Trends of Evolution) tells us that stepping from 'solid' to 'liquid' enables the system to perform various functions better (e.g., mixing, healthy looking, cold mixing, dissolving, etc.). All the property words listed up at first contribute to produce similar suggestions as shown in the figure. With these suggestions of new properties varied into the next stage along the Trends, one can imagine different new products.

The second type of DIVA process is to think of the desirable functions of a new product to be evolved from the current product. With some minor change in the scheme of the above figure, matching with the desirable function suggests possible desirable properties for the new product.

The third type of DIVA process is to suggest possible ways of resolving conflicts between two properties (e.g., weight vs strength). The software tool suggest to think of introducing/enhancing a third property (e.g., porosity, fragmentation, etc.); this corresponds to suggesting TRIZ inventive principles for solving technical contradictions, the authors say.

*** The concepts proposed in this presentation seem to have a lot of possibilities in a simple scheme. The paper is written somewhat in an intuitive way; it is much desired that the authors to develop their concepts further and demonstrate them with their software tools.

(D) Case Studies of TRIZ for Problem Solving

Siegfried Luger, Arno Grabher-Meyer (Luger Research, Austria) and Gerhard Kottek (Electro-Terminal, Austria) [7] reported a case with the title of : "Reviewing an Innovation Project for a New Electrical Terminal". This was a project in a Six-Sigma framework seeking for a innovative concept of a platform of an electrical terminal. The main requirements for a new platform are: Usable for a wide range of the wire cross sections, usable for different wiring type (in different countries), easy to use, and fulfilling the worldwide security and installation standards. The project used TRIZ. First they defined the ideality for an electrical terminal: Maximum pressing force to the wire, no force necessary for connecting the wire and for reconnecting (or releasing) the wire, etc. With the suggestions of TRIZ Trends of evolution and Inventive principles, they have obtained an idea as shown in the following figures (left: schematic concept; right: the product). This idea also reflected a hint from a pine needle pair, with which the chief engineer was somehow impressed months before.

Valery Krasnoslobodtsev and Richard Langevin (Technical Innovation Center, USA) [8] presented a detailed case study of "TRIZ Development of Robotic Vacuum Cleaner". This is the third of the author's series of detailed presentation of solving real problems [See TRIZCON2005 and TRIZ Symposium in Japan 2005

]. The present case was achieved in the TRIZ team of Samsung Electronics, Korea, during 2001-2002. The brought-in problem was to improve the features of the Samsung robotic vacuum cleaner, especially in the following 4 aspects: (1) To increase cleaning capacity, (2) to clean edge places better, (3) to clean corners better, and (4) to clean slot areas (e.g., under the sofa) under the condition of no-increase in the suction power consumption and of preserving circle-shaped body.

It is remarkable that the present paper explains their solution processes in detail for the four problems. They used an abbreviated seven-step version of ARIZ. The authors explain their process step by step as follows for the case of the first problem:

(a) Customer Problem statement: The customer (i.e., Samsung's engineering team) has a problem that the conventional robotic vacuum cleaners do not remove contaminants completely, especially fine contaminants embedded in a carpet or stuck to the cleaning surface. Cleaning capability should be increased without raising the suction power consumption.

(b) Formulating the problem with technical contradiction:

(c) Formulating the problem with physical contradiction: 'The air force at the suction port should be strong for removing the fine contaminants and should be weak for decreasing the electrical power consumption.'

(d) Defining Ideal Final Results:

(e) Resource analysis: Product: contaminants; Tool: air flow; Super-system: suction air and port, exhausted air and port, motor, wheel, sensors, etc.

(f) Generating the specific solutions: For solving the physical contradiction, separating contradictory requirements in space was applied. The first proposal was to add a new force (or field) in the form of the brushing motion only at the operation zone.

The second proposal was obtained by considering the resource of the Super-system and introducing an air jet at the operation zone with a circulation of the exhausted air (see the figure below). The left figure is the scheme of vacuum cleaning, including air suction, filtering, pumping for air suction & compression, and air jet at the operation zone. The center figure shows the schematic side section view, while the right figure the flat section view. At the operation zone of cleaning the floor (or carpet etc.), the air jet is applied through several small outlets to move the contaminants with the help of brush, and the resultant dusty air is suctioned away. As shown in the figure, this operation zone is enclosed with elastic skirts so as to prevent the contaminants from being dispersed outwardly. This proposal approximates the ideal solution, the authors say, because the robot itself provides resolution of indicated contradiction by using just the internal resources of the system with minimal modification of the cleaner.

The paper describes the solution process and solution concepts, in detail in the similar way, for all the four problems mentioned above.

*** This paper is very useful to study how to solve real problems in a standard way of TRIZ (i.e., in a slightly simplified but close to the standard ARIZ-85B). The logical process and the concepts of solutions are described thoughtfully without hiding any essence of ideas. During the session's discussion, several people asked about comparison of commercial robotic vacuum cleaners made by Samsung and by other companies. They asked such questions probably because this paper presented interesting solution concepts some of which have been implemented in the commercial products. However, in the conference of TRIZ methodology and its applications, we should learn much more about how to solve problems than about the solutions themselves and their commercial results. This point should be remarked, I believe, on our treatment of case studies and especially 'success stories'.

Juerg Spieler (ALVEO AG, Switzerland) and Peter Schweizer (MethoSys GmbH, Switzerland) [39] talked about "CAI-Based Innovation Management at ALVEO AG". This paper gives a case of introducing & promoting TRIZ-based software tools (specifically, IMC's TechOptimizer, Knowledgist, and Goldfire Innovator) to a manufacturing company of cross-linked polyolefin foams for mostly automobiles. A project of developing 'a heavy foam' was carried out in the following way:

(1) First we set up a model of automobile and analyzed where in the model our main products (polyolefin foams with the specific weight of 0.24) could be used. As a result of this research, we found the needs for 'heavy layers' for avoiding and reducing vibrations and sounds.

(2) On the basis of the patent research using the tool's S-A-O semantics, we have found that today's cars contain in the average 24 kg of heavy layers with the specific weight of 0.7.

(3) Now we considered how to produce 'heavy foams', with the help of the TRIZ tool (TechOptimizer). There were three possibilities of modifying the current production, i.e. additives in the foam, extrusion process, and foaming process. The conclusion was that it is possible to produce heavy foam with a specific weight of 0.55 on the company's existing equipment.

(4) The produced heavy foam was tested in the lab to find the significantly better property for damping vibration and sound. The softness combined with greater mass was found effective for better damping with less weight.

(5) Based on the knowledge of heavy foam, we started to develop a portfolio of completely new products. More market analysis was carried out with the help of Goldfire Innovator, and more possible applications of the product foams in the automotive sector were recognized. This finding is expected to reduce our current large catalog of products into smaller one with new better products.

*** This case study looks very simple and straight forward, but so much so we can learn a lot in the whole process. This case demonstrates well how to use the patent analysis for marketing as well as technology research.

(E) TRIZ Methods for Strategic Development of New Products and Technology Prediction

It was most noticeable in the present ETRIA Conference that several presentations discussed on the TRIZ methods for strategic development of new products and for technology prediction/forecast. Industries want such methods even more than the methods of problem solving because they have to decide their strategy beforehand and invest much on the basis of such decisions.

Len Malinin (GEN3 Partners, USA) [9] talked about "Trends of Evolution of Engineering Systems Help Designers to Develop Next Generation Products". He demonstrated the usage of TRIZ Trends of Engineering Systems in three cases. In the first case, the future of the hand-held hammer drills for concrete, bricks, etc. is discussed. The merits of electro-magnetic hammer drills are discussed over the compression-vacuum type. In the second case, future of apparatus for dispersion and homogenization of viscous liquids is discussed along the trends of Segmentation of the working tool. Cavitation-based disperser is proposed; it utilizes gases as the working tool and it really converts the harmful effect of cavitation into useful function. In the third case, new methods for chopping glass fibers are discussed. Replacing the current mechanical chopping method with a commercially available technology of aerodynamic forming and electro-static flocking was proposed.

*** These three case studies suggest the importance of viewing technologies from the fundamental mechanisms of their functions.

Darrell Mann (Systematic Innovation, UK) [17] discussed "On Innovation Timing". Even though TRIZ can uniquely predict discontinuous-evolution (i.e., innovation) of technology, it has been relatively weak in answering when a particular innovation step is or is not likely to succeed in the market, because the myriad different factors can influence the final success-or-failure outcome, the author says. Thus the author tries to give a helicopter view of the issue after discussing several factors. Classifying the final timing into three, i.e., 'Never', 'Now', and 'Sometime in the future', the author has found the flowchart algorithm for evaluating the innovation timing, as demonstrated in the following figure:

The first criterion for successful innovation is 'whether the business model of the innovation product/service is viable?'. In viable business model there must be the following five components: Means of production, Route to market, More ideal product/service, Market demand, and Co-ordination (see Darrell Mann, "Hands-On Systematic Innovation for Business and Management", IFR Press, 2004). If the answer is 'No', the innovation timing is 'Never' until you achieve the viability conditions. The second criterion is 'whether the innovation is a genuine breakthrough and is developed/pursued by a large player?'. The third is 'whether a hidden failure of the proceeding technology/business is definitely found or a symbiogenesis of two existing technologies/businesses is found?'. If you find YES in either the second or the third criterion, the innovation timing for you is 'Right now'. In case of 'No' for these two criteria, then the innovation timing is likely to depend on various delicate factors (or 'If's'), they include: Level and type of trade-offs present in the (non-genuinely innovative) new product/service; Conflicts emerging from different customer trends; and (in case of an incremental innovation) Position on the S-curve and prevailing customer expectations; and the overall rate of discontinuity evolution in the relevant field of the product/service. The innovation timing may depend on these factors, and we are not ready yet to calculate the timing, thus at moment the answer is just 'Sometime in the future', the author says.

*** The above algorithm is qualitative in evaluating the innovation timing, but we can learn a lot what is most important for successful innovation as a business.

Hansjuergen Linde, Gunther Herr, and Andreas Rehklau (WOIS Institut Coburg, Germany) [30] gave a presentation with the title of "Mastering Strategic Innovations contra Location Crisis: Contradiction-Oriented Innovations Strategy WOIS, Based on TRIZ". The authors have been promoting WOIS as the methodology for strategic innovation; and they gave a Keynote speech last year at ETRIA TFC 2004. This year they gave an overview of their methodology WOIS with placing stress on the decision making at the early stage of product development. They say that future-oriented companies require a system that consists of a growth oriented economical model, an energy focusing philosophy, a culture of a commonly shared understanding concerning future challenges, and knowledge about hidden pattern of competition. WOIS's model of strategic decision is 'shortcutting the spiral of evolution'. For achieving it, three phases should be carried out; they include direction finding, decision finding, and innovation finding. Overview of the processes necessary for these phases are described briefly. Two slides shown in the last year's Personal Report of ETRIA TFC 2004 are most representative for this year's talk, too.

Dmitry Kucharavy and Roland De Guio (INSA Strasbourg, France) [18] gave a presentation on "Problems of Forecast". This paper discusses seriously about the problems, i.e. difficulties, in making reliable forecasting, as a reflection of their experiences of the project with the European Institute for Energy Research (EIfER, Karlsruhe). 'Technology forecasting is a comprehensible description of emergence, performance, features, or impacts of a technology at some time in the future in defined place', the authors define (especially in contrast to future technology planning and scenario writing). The difficulties are more serious in cases of medium and long-term forecasting of new family of products and new-to-the-world technologies. The authors consider four stages of life-cycle of forecasting itself; the stages are: Designing of forecast, Developing forecast models, Applying the forecast, and Retiring/updating forecast models. They have listed various difficulties especially associated in the first and second stages. The authors describe their projects with EIfER for forecasting the future of Stationary Fuel Cell technology, showing some preliminary results by using radar plots of critical features and 'Contradiction network'.

*** This paper is just preliminary in the sense of their methods and their results, but worthy of reading for understanding the difficulties of technology forecasting in any reliable way.

Peter Chuksin and Nikolay Shpakovsky (INTEKO-TRIZ, Russia) [31] talked on "Analysis and Representation of Information in Forecasting". The forecast of technical systems development builds up not a separate decision, but a field or a tree of decisions having significant variability and information redundancy. Thus the representation of such decisions is important for the forecasting analysis and for presenting the results, the authors say. They have built and used a method of forecasting mostly using the knowledge of TRIZ Trends of Evolution and representing the results in a tree diagram, i.e. Evolution Tree. See an example of it in their paper of ETRIA TFC 2002 (in my 'Personal Report' ). The present paper mainly descries the rules of drawing the Evolution Trees.

Guenther Schuh, Markus Grawatsch, and Markus Wellensiek (Fraunhofer Institute for Production Technology, Germany) [37] gave a nice presentation with the title of "Technology Intelligence: Defining the Potential of Emerging Technologies". Technology Intelligence is defined (in accordance with Savioz, 2002) as 'activities that support decision-making of technological and general management concerns by taking advantages of a well-timed preparation of relevant information on technological facts and trends (opportunities and threats) of the organization's environment by means of collection, analysis and dissemination'. To analyze the potential of a technology and to forecast its evolution, TRIZ offers several methods, including the S-curve analysis which has been used indifferent publications. The S-curve analysis, however, the authors say, is difficult to apply and contains a high uncertainty in the results, according to experiences. Thus, the authors have tried to combine several methods (which offer results with similar uncertainties) to gain results with a higher validity. The methods include TRIZ' Trends of technological evolution, systems theory, and morphology. They have built a TRIZ-based technology intelligence method and have demonstrated its six-stage application to the fuel cell technology.

The method is based on two hypotheses, the authors say. First, the potential of product technologies which fulfill the same primary function can be assessed only relatively to each other. (Thus, in the example, the fuel cell technology was examined together with the lithium ion accumulator technology.) Second, a sufficiently precise estimation of the potential of a product technology needs its consideration from various points of view. Thus, many methods in TRIZ (such as Function/attribute analysis, Ideality, Contradictions, Trends of technological evolution, and S-curve) and in TRIZ-related methods (such as systems theory and morphology) are integrated in the new approach. The new Technology Intelligence method proceeds in six stages as follows:

(1) Search Field: First we put the Fuel Cell as the target product technology at the system level, having its main function of 'supply of electric energy'. Considering its super-systems, cases of its applications are listed (including camcorder, laptop PC, tools (e.g. drilling machine), and cell phone) and their demands on the product technologies are clarified. Then, at the sub-system level, subordinate technologies are considered by listing up the Fuel Cell's principal sub-functions. The sub-functions include to convert energy, to store energy, and to control the system, etc. Elements for performing sub-functions are also considered. Finally, the reference system was chosen to be the lithium ion accumulator, as it is the current technology having highest energy density and capability.

(2) Life Cycle: The positions of the two relevant technologies on their S-curves need to be assessed through various information, e.g. patents, literatures, experts, or markets. The accumulator technology is found at the growth to the maturity phase, while the fuel cell technology is found on the threshold from the emerging to the growth phase.

(3) Technological Capability: By the modified application of the TRIZ Ideality principle, the manifold performance parameters of an existing or emerging technology is reduced into one key figure, i.e. the Technological Capability (TC). The model for calculating the TC is shown in the figure below. First we should define several Performance parameters to represent the Useful and Harmful functions, and evaluate their relative weights by using the standard procedure in QFD (Quality Function Deployment). For the currently-existing reference system, the actual values of these parameters are evaluated, and the parameter values for the target system and for the reference system are to be expressed after normalizing with these reference values. Thus, the Technological Capability (TC) is calculated by the equation:

TC = Sum of (normalized weight x normalized positive parameter values)/Sum of (normalized weight x normalized negative parameter values)

In the case of present example, five parameters were chosen: energy (+), volume (-), weight (-), voltage (+), and cost (-). In reference to the lithium ion accumulators in the market, the parameters for the current-level of fuel cells gives the TC value of 0.052, a value not competitive at all.

(4) Development Possibilities: Possible innovations in the competing technologies and their subordinate functions are derived by literature investigation and application of TRIZ Trends of technological evolutions.

(5) Technological Capability Limit: Then possible limit in each of the parameter values is evaluated. In this evaluation, some of contradictions in the current technologies are assumed to be solved in future in their innovation process. In the case of Fuel Cell, the possible limit of energy is evaluated to be 1.26 kWh, with the assumptions: Maximum efficiency of conversion = 50 %; the energy converter and periphery has only 10 % of volume in the whole device; Max. energy density of propane = 7.5 kWh/l; Volume = 0.37 l. Similarly with the estimation of limits as: Weight = 0.22 kg; Voltage = 11.1 V; Cost = 183.8 Euro. This gives the limit value of TC = 16.6 for the fuel cell, in contrast to 4.95 for the accumulator technology.

(6) Technology Potential: Based on the information accumulated above, the TC values for the two systems can be summarized in an S-curve covering the past, present, and future. See the following figure for the Fuel Cell and the lithium ion accumulator technologies. The authors estimate that the Fuel Cell technology will reach the capability of the accumulators in 15 years at the earliest. The R&D activities and the financing for supporting R&D will determine the timing of the crossing (or no crossing).

In the conclusion, the authors critically notice the difficulties in the present method: The anticipated progress of the technological evolution depends on so much factors that it is impossible to cover all their possibilities; historic performance parameters are difficult to investigate; the calculation of TC is not definite because of the subjective weighting of the performance parameters. Nevertheless, the Technology Intelligence method demonstrated here is widely applicable and adaptable to future changes.

*** This is a nice method for analyzing the potential of competing and emerging technologies. The process of calculating the key parameter, TC, is mostly transparent. Thus the reliability of the results can be discussed openly.

(F) Extension of TRIZ Application Fields in Technologies

Toru Nakagawa (Osaka Gakuin University, Japan) [32] gave a presentation with the title of "Software Engineering and TRIZ (2): Step-wise Refinement and the Jackson Method Reviewed with TRIZ". I would like to quote my Abstract below:

We have been examining major topics in software engineering (SE) one by one with the aims (1) to clarify them with the views of TRIZ, (2) to feed the principles/knowledge in SE and computer science back into TRIZ, and thus (3) to extend the application field of TRIZ into software development.

The concept of Step-wise Refinement is in harmony with TRIZ principles such as Segmentation and Local Quality, but is more advanced in its logical way of description. We notice a case of 'poor practice resulting in the redesigning' in the sense of SE can be regarded from TRIZ as a good and natural practice of refinement applying the Segmentation of problem in 'Another Dimension'.

The Jackson Method (or Jackson Structured Programming) proposes to build the structure of the processing system in accordance with the data structures of inputs and outputs. Though TRIZ has a similar concept to model the system in accordance with the structure of its objects/environment/super-systems, TRIZ can learn more from the software concepts and techniques. The 'Prior-reading technique' is also discussed.

In these basic areas of software development, TRIZ is in harmony with SE and can learn more from it.

The case mentioned above as a 'poor practice of Step-wise Refinement' in the sense of Software Engineering but regarded as a 'good practice of refinement' by using the Segmentation of problem in Another Dimension in the sense of TRIZ is illustrated below:

This paper is [going to be] posted in my Web site "TRIZ Home Page in Japan", together with my preceding paper of "Software Engineering and TRIZ (1): Structured Programming Reviewed with TRIZ"

(presented at TRIZCON2005).

Alexander Kynin, Seunglhee Suh, and Seungheon Han (Samsung, Korea) [22] gave a paper with the title "As the 'Smart Materials' Can Help the Inventor". Discussing different definitions of "Smart Materials", the authors give the following definition:

"Smart material" is a substance which at achievement by external influence of threshold value transforms quantitative change of energy of this influence to change of own properties. This change is qualitative and spasmodic. At this change the material carries out useful function. Performance of this useful function can as repeated, and repeating at reduction of external influence, and unitary.

Then they classify smart materials into four subgroups and have made a database of existing examples, they say.

*** However, this paper is just an extended abstract of 3 pages without showing any detailed information. I do not know how was their presentation at the conference. [The sentences in the above definition of "smart material" are too confusing for me even to speculate.]

(G) Integration of TRIZ with Relevant Methods

Dmitri Wolfson (Galgano e Associati ) and Sergei Ikovenko (GEN3 Partners, USA) [14] gave a nice introductory paper to the integration of TRZ with Toyota Production System, or Lean Engineering, with the title of "The Case of Simplification - Rapid POKA YOKE Development Using TRIZ". Here is the Abstract of the paper:

Lean Manufacturing distinguishes between activities that add value for the customer and those that do no. The latter are composed of two types of activities: a "necessary evil" and an outright waste. Lean companies learn to recognize and eliminate any form of waste. When the root cause analysis is performed, it becomes clear that the majority of unnecessary process originates from simple errors or ineffective cost avoidance techniques. There is a humble weapon in the Lean Manufacturing arsenal of war on waste, that is called Poka-Yoke (Mistake Proofing). It is an ingenious device that does not allow an error to be made, thus avoiding the harmful propagation of its consequences in the complex environments of today.

The concept of Poka-Yoke echoes with many major TRIZ and TRIZ-related approaches and tools. TRIZ can significantly enhance quality and availability of Poka-Yoke devices, facilitating application of other Lean tools and augmenting the bottom-line impact of overall Lean implementation.

The first half of this paper is a brief but excellent introduction of the philosophy and practices of Lean Engineering (or Toyota Production System).

*** This Japanese engineering philosophy has a lot of deep insights, which often seems impossible, incorrect, and paradoxical at first. Please read the text of this paper and a similar introductory paper by Steven Ungvari presented in TRIZCON2005 . Brief comments about original Japanese meaning: 'Poka': an informal word meaning careless mistake; 'Yoke': pronounced as 'yokeh', meaning avoiding/preventing; 'Jidoka' (or 'Jidohka', but not 'Jidokha' as in this paper): autonomation.

In the latter half of the paper, the authors show four actual cases of providing Poka-Yoke devices or solutions by use of TRIZ principles and methods.

*** The combination of the needs for Poka-Yoke devices/solutions and the TRIZ capability for providing appropriate principles and solution methods is so smooth in the paper that the usefulness of TRIZ in the Lean Engineering is demonstrated clearly.

*** This paper is suggestive indeed especially to our Japanese people in industries. At moment in Japan, the TRIZ community and the people promoting Toyota Production System have very few chances of discussing and collaborating in actual cases. Around 1994-1999, Mr. Hiroshi Igata, a young engineer working for Toyota was the pioneer of mastering IM Lab software tools and introducing TRIZ to Japan with his Web site. Thus Toyota had chances of being exposed with TRIZ (and with USIT through Ed Sickafus' presentation) but apparently did not show interests in it. Recently since 2003, Denso Co., a world-leading company of automotive equipments and car-electronics in the Toyota group, has been introducing TRIZ actively. On the other hand, many industries in Japan (and in the World) are much interested in Toyota Production System, especially due to years-long success of Toyota. We, the TRIZ community in Japan, have to work harder to understand different methods and movements for innovation and to cooperate with people having different backgrounds. This is also true for the TRIZ communities in all other countries, I suppose.

Kyeong Won Lee and Young Joon Ahn (Korea Polytechnic University, Korea) [19] gave a paper on "Mutual Compensation of TRIZ and Axiomatic Design". This is just a review of Axiomatic Design (developed by Nam Suh) and TRIZ with some emphasis on how to treat a system having multiple functions. Kyeong Won Lee once told me that Axiomatic Design is popular in Korea.

Jeong-Ho Kim and Young-Ju Kang (LS-Cable, Korea) [23] gave a presentation with the title of "R&D Process Aided by Computational Analysis and TRIZ in LS-Cable; and Case Study". The team of VEA (Value Engineering Analysis) + TRIZ in LS-Cable worked together with the CAE group to solve a real mechanical problem. The CAE methods were used successfully in the problem analysis stage of TRIZ as well as the solution evaluation stage. This combination of TRIZ + CAE is quite natural (and widely used, I suppose) because the CAE-based simulation serves as quite a reliable means of experiments (in computers).

Johannes Pfister (InterQuality Service AG, Germany) [24] gave a very informative paper with the title of "Success Through Integration of TRIZ, DFSS and Strategic Management". This is a trial to build up a holistic model for technology development by integrating various methodologies on the basis of the author's experiences of thirty years as a consultant. I would like to quote his Abstract first: